Removal / replacement of the dead 'clock backup' coin cell in an Icom IC-7300 and IC-9700

by Wolfgang Buescher, DL4YHF

last updated: November 2023.

▄bersetzung in's Deusche (Google Translate, requires Javascript)

Traduction en franšais

This document describes the removal of the 1 mAh 'clock backup' accumulator

coin cell ("ML414H") in an Icom IC-7300. The web is full of info about this annoying 'feature',

which not only affects the IC-7300, but it will sooner or later haunt

your IC-9700, and maybe similar rigs, too.

The author didn't want to replace the stupid 1 mAh Lithium-Ion cell by another cell of the same type,

only to find it dead a few years later again.

The cell isn't really vital (its death won't affect channel memories and settings), but to the

author, it was annoying to have such a nice radio with a non-functional built-in calendar and clock.

Beware: The original circuit is designed to recharge the orginal accumulator cell, even though very slowly.

Doing this with a primary cell ('Batterie') may be hazardous, causing the electrolyte to leak out and damage nearby components.

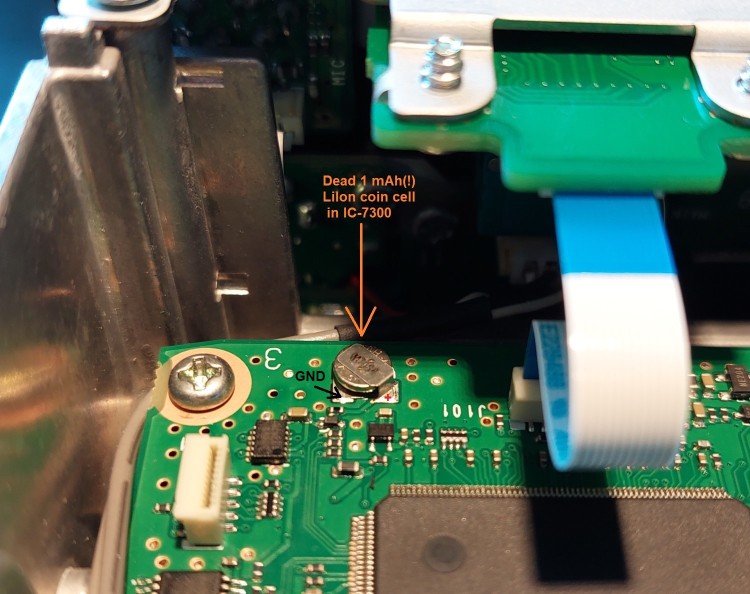

1. Removal of the original 1 mAh Lithium-Ion cell (ML414H) in an IC-7300

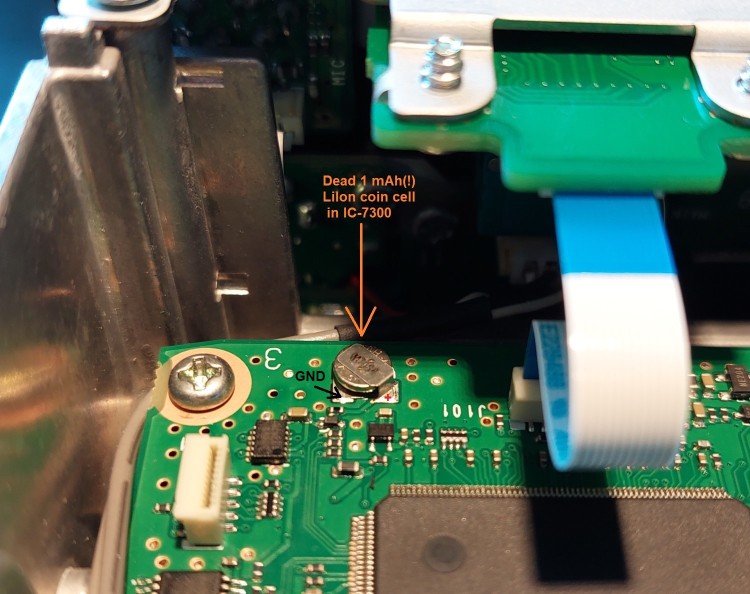

Remove the IC-7300's bottom-side cover. The culprit sits in a corner of the CPU circuit board,

near the display. There's no need to unplug all those cables, or the board,

or anything in the IC-7300. (Spoiler: In the IC-9700, things are different..)

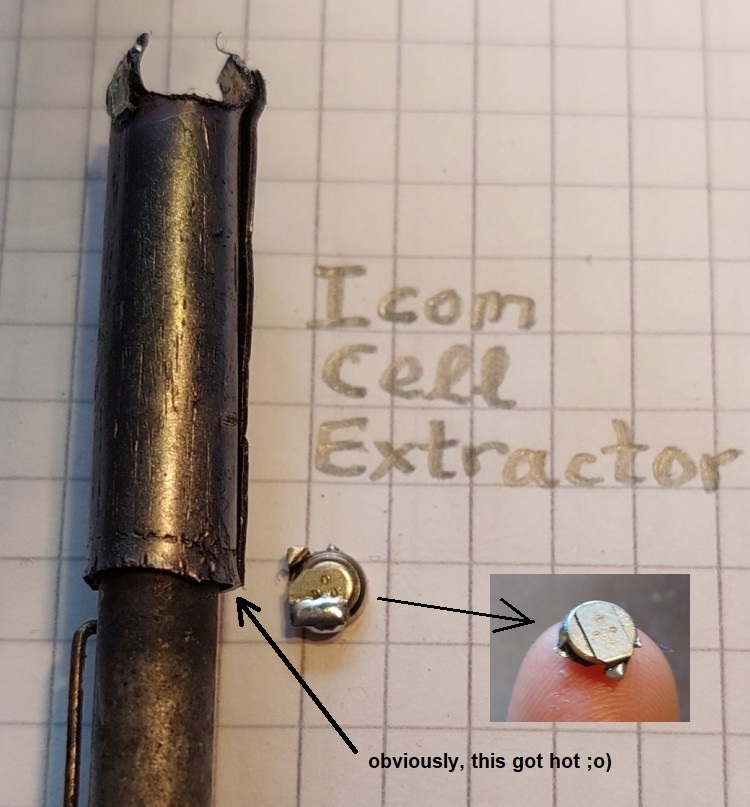

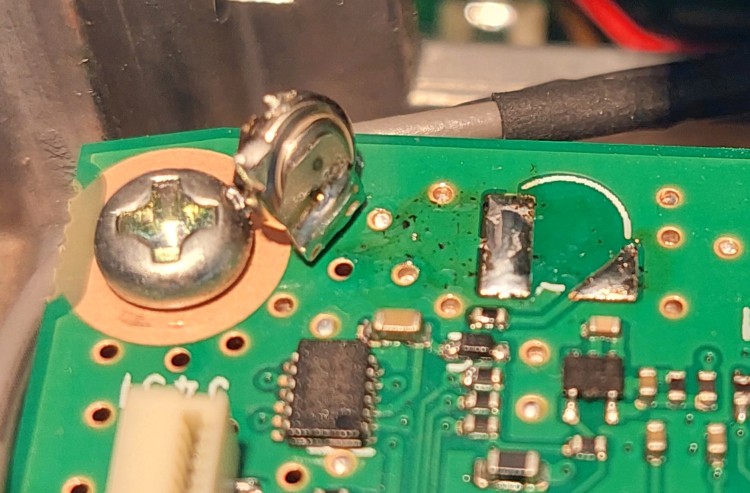

Photo of the culprit - Icom's glorious LiIon coin cell with an incredible

capacity of 1 mAh, shortly before 'brutal removal' as explained below.

If the cell wasn't an SMD part (surface mount), it would be easy to be remove

by simply cutting two wires, or beding it from one side to anoter while heating it

with the soldering iron, and gently pulling it out. No chance here. You need to get

both 'terminals' hot at the same time, and with the tin melted, swipe the cell

off the board - and of course, without flooding everything with a large amount

of molten tin, to let the cell 'swim', hi.

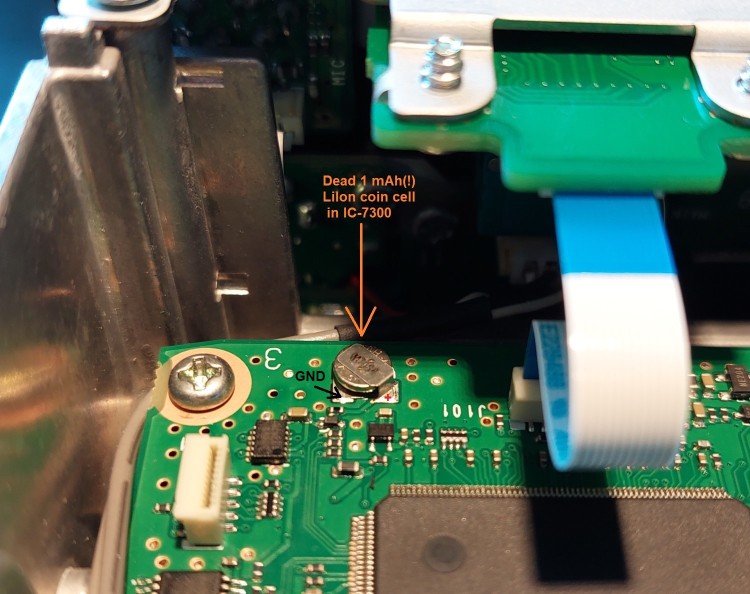

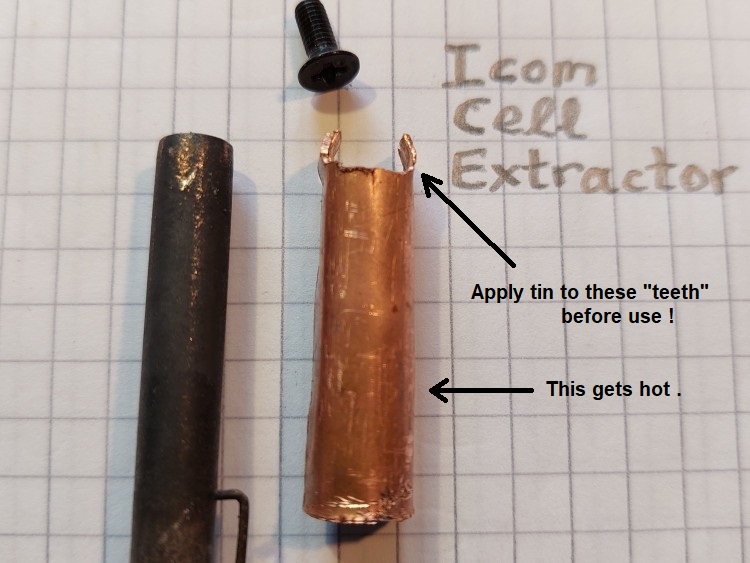

Similar as in other repair cases, a 'component removal tool' was made from

a strip of copper sheet metal (0.5 mm thick), rolled together to form a tube,

with the inner diameter matching the OD of the soldering iron. Then, with a small

cut-off wheel and a motor tool, remote a part of the copper to give the

'Icom Cell Remover' its final, tweezers-like shape (just wide enough for the

to-be-removed coin cell with 5 mm diameter).

The "Icom Cell Extractor", rolled from copper sheet metal,

to match the diameter of the soldering iron (here: Ersa, shown on the left)

The 'Extractor' tips were tinned in advance to make good thermal contact

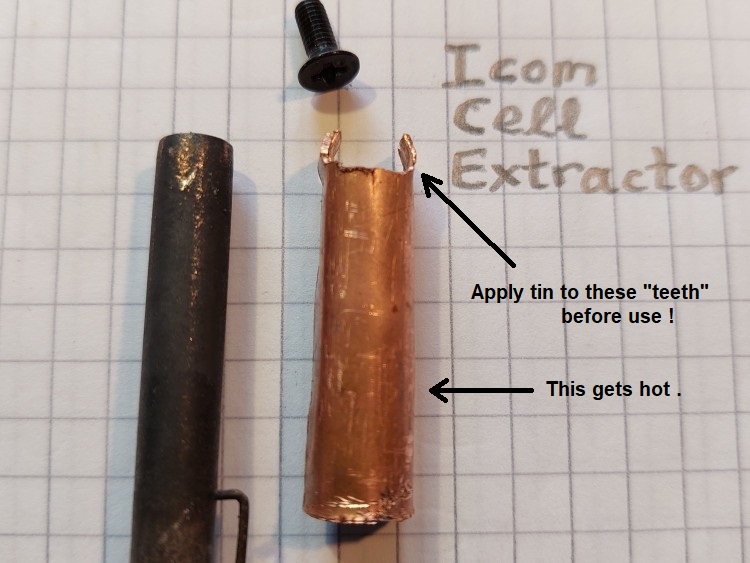

with the pads, on both sides of the cell. Then, heated up to 350░ C, it was

slipped over the dead cell ("no mercy" - the cell was dead anyway, so fry the

little bastard). After a few seconds, without using any significant

fource, the fried battery could be swiped to the corner of the

CPU board (where fortunately it stopped, after getting in contact with one

of the screws holding the PCB), without ripping off traces:

Photo with the dead cell after the 'Cell Extractor' performed its work in an IC-7300.

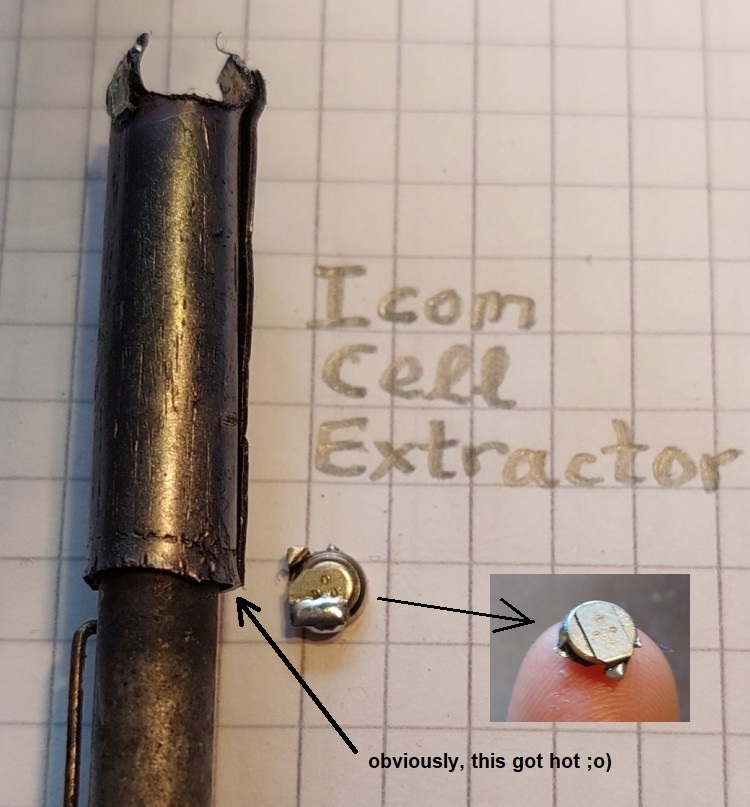

The 'Extractor' was kept for later, because the cell in the author's

IC-9700 will also die sooner or later ("thanks" to the incredibly large

capacity, and the limited cell lifetime of only of a few hundred

charge / discharge cycles).

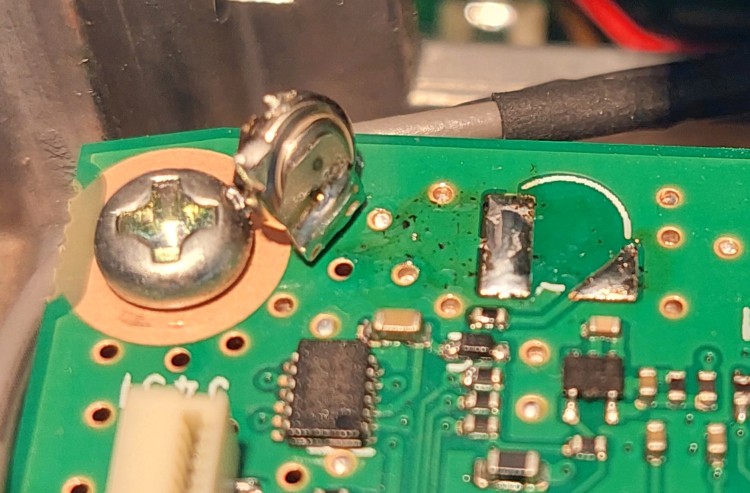

The 'Icom Cell Extractor' and its prey; "grilled and ready for the waste bin".

2. Replacement of the dead cell with two Ultracaps (connected in series for the voltage rating)

Instead of replacing the LiIon rechargable cell with a Lithium battery (which would have

required a diode to protect it from being charged), the LiIon cell was replaced

by two Ultracaps in series, with 5 Farad, 2.7 Volts each.

Use a good brand name (like Maxwell), don't buy crap from you-know-where

with either high leakage current, large production spread, less-than-specified capacity,

high series resistance, or just waste.

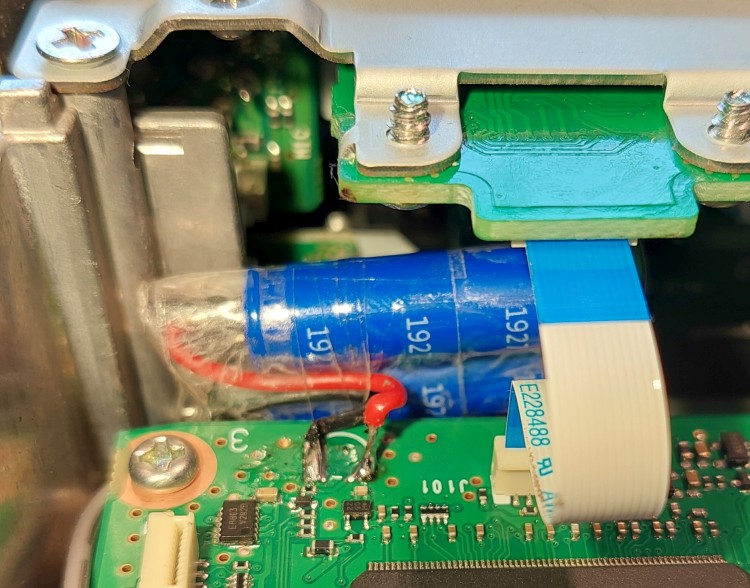

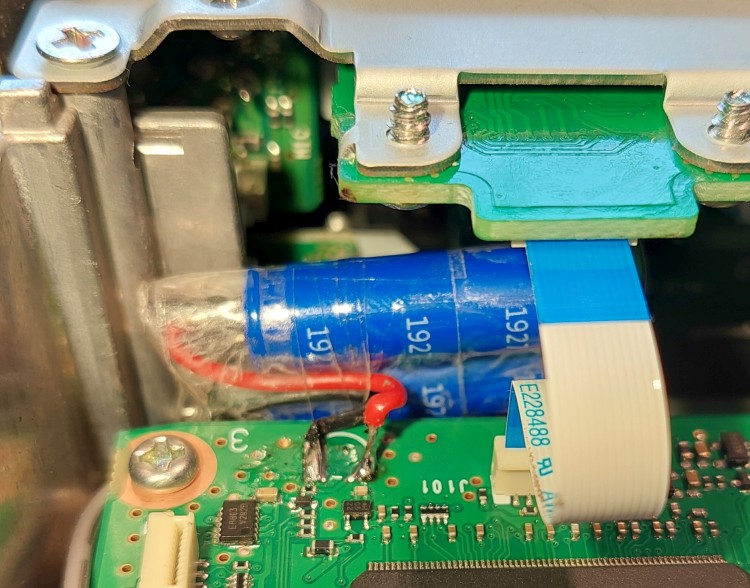

Dead cell replaced with two 'Ultracaps' in series,

IC-7300, wrapped with adhesive tape for safety.

Before installing these capactors in the Icom, they were tested for their

leakage current as described further below. It turned out that the

'guaranteed' maximum leakage specified in the Maxwell "HC Series Ultracapacitors"

datasheet was quite pessimistic - in the fact, the leakage current,

with the charge capacitors stored at room temperature was far less

than specified - in other words: For this purpose, the capacitors were

much better than expected. As already noted in the introduction,

the capacitors were not bought at Ama.., Eba.., Ali.. but at a trustable source.

After slowly charging them to 5 Volts (already connected in series,

with almost perfectly 2.5 Volts per capacitor), and leaving them connected

to the 'charger' for couple of weeks, their internal leakage current

was so low, that the voltage only dropped from 5 to 4 Volts

after several months ! If you're concerned about leakage

current as the author was (before simply trying it), consider this:

In the Icom, the maximum charge voltage is only 3.3 V, thus only 1.6 V

per Ultracap, so the expected leakage current will be even smaller

when used in the Icom.

Note: Before installing the two caps in the radio, make sure that

both caps are equally charged to say 1 Volt per cap. Never exceed

1.6 V per capacitor, or 3.3 V in total !

When pre-charged this way, you don't need to wait for a couple of hours

to let the Icom's original "charger" (3.3 kOhm resistor) charge it.

To check for the Ultracap charging speed, the voltage accoss the caps

was measured during a 10-minute test, with the radio turned on

(or at least connected to an external power supply, which also causes

the weak charging current for the ex-LiIon-cell to flow):

Begin of test: 2.63 V

10 minutes later: 2.66 V

That's a voltage increase of 30 mV in ten minutes, or circa 180 mV per hour.

Ok but not really fast (see next chapter about the modification

of an IC-9700, where the original 3.3 kOhm series resistor was

replaced by 330 Ohm to charge the Ultracaps completely within

two hours).

3. Removal / replacement of the original 1 mAh Lithium-Ion cell (ML414H) in an IC-9700

A few months after the IC-7300's clock battery's demise, the battery in the author's

IC-9700 died, too. Suprisingly, this happened after only one night without

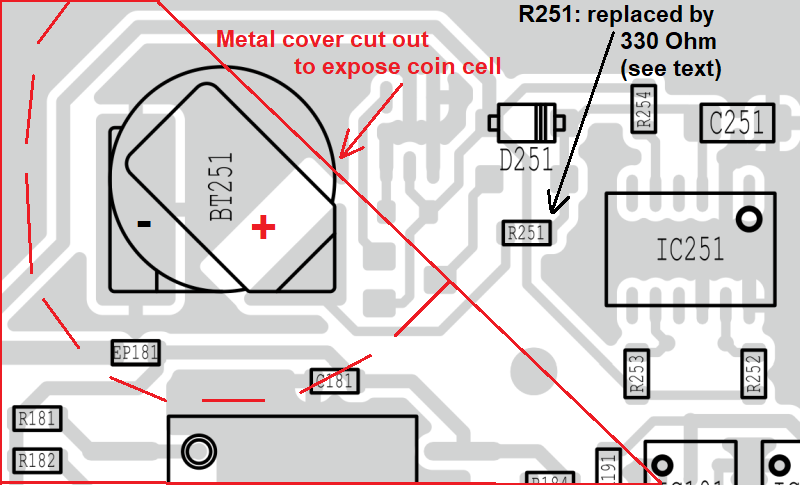

being connected to external DC power. Unfortunately, in the IC-9700, Icom has hidden

the dreadful ML414H (in the IC-9700, component number 'BT251', near 'IC251') under

a large metal "roof" soldered(!) on the 'Main Unit'. The main unit is on the underside

of the transceiver, so you only need to remove the bottom cover to see

the 'Main Unit' - but you still will not see the ML414H cell:

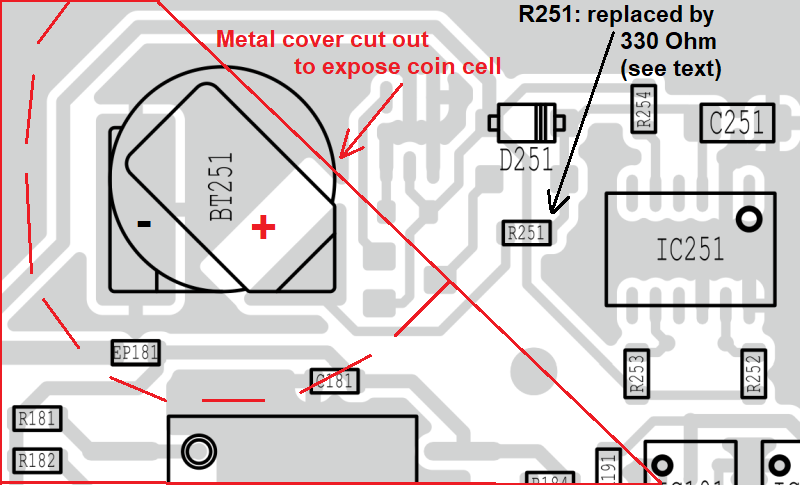

Layout of the IC-9700's main unit, with the dreadful coin cell ('BT251') hidden below

a sheet metal "roof" (edges marked in red, the dashed half circle marks the cut-out area).

An attempt to unsolder the irregular-shaped metal "roof" above the CPU, coin cell,

and many other components failed (too many points that would have to be heated

simultaneously, marked by red arrows in the photo further below). Because the

coin cell is near the edge of the "metal roof", a rounded area just above

the cell was cut away - very ugly, but much easier than a proper removal.

The sheet metal over the coin cell is quite thin, so could be cut from the edge

with sharp scissors, and then 'rolled up' in a half circle

like the lid of a tinned fish can. Then, the cell was unsoldered

as already shown for the IC-7300 further above.

Dead cell replaced by two 'Ultracaps' in series, here in the IC-9700,

glued to the metal shielding ("roof") above the main unit's PCB.

The 100 Ohm resistor visible between the two capacitors

was used to measure the charge- and discharge current.

The two 10-Farad, 2.7 Volt Ultracaps in series (*)

were glued to the sheet metal. For quicker charging, R251 (3.3 kOhm

in the original circit) was replaced by a 330 Ohm SMD resistor. With this resistor,

the initial charge current for a completely discharged Ultracap

would be about 10 mA. After installing the two completely discharged Ultracaps

(for safety), two hours after turning on the IC-9700, the voltage across the caps

reached 2.8 V.

(*) Having run out of 2.7 V / 5 F Ultracaps,

for the IC-9700 repair, easily available 10 F / 2.7 V Ultracaps by Maxwell,

type "BCAP0010 P270 S01", were used. Buy at Mouser or Digikey.)

4. Estimate of the maximum 'clock reserve' after replacing the original ML414H with Ultracaps

From the datasheet of the IC-7300's RTC (Real-Time Clock), type RX-8803LC:

- Minimum clock supply voltage = 1.6 V

- Typical current consumption in 'Backup Mode' = 0.75 uA at Vdd=3 Volt

- Maximum current consumption in 'Backup Mode' = 2.1 uA at Vdd=3 Volt

We're optimitic and assume the "typical" current consumtion (which is justified

because we don't operate the IC-7300 at +85░C in standby, where a semiconductor

like the RTC would draw more leakage current than at room temperature).

With the Ultracaps charged to say 3.2 V (it will never reach 3.3 V due to the

discharge-preventing diode, D381 in the IC-7300, D251 in the IC-9700),

the voltage across the caps may drop by 3.2 V - 1.6 V = 1.6 V before the

clock / calendar stops.

With C = 2.5 Farad (remember, two 5-Farad-Ultracaps in series), that's

T = delta U * C / I = 1.6 V * 2.5 F / 0.75 uA = 5.3*10^6 seconds = 61 days at best.

That's not spectacularly long, but:

Much in contrast to a LiIon cell, which inevitably dies

from a deep discharge, modern Ultracaps tolerate this and don't need to be

replaced every few years.

If you really removed your radio that long from a power supply, it will need

to have the time-and-date set again (or, for the IC-9700, be synchronized

via Internet) - but after leaving the radio connected to DC power for a day,

the clock will be working again for at least a month.

So far, neither the author's modified IC-7300 nor the modified IC-9700

has ever suffered from a lost calendar date/time,

even after being "power-less" for several weeks.

back to DL4YHF's main ham radio homepage