If you have ever had to open the trunk of your GL in the dark to root around for something you know why I wanted to install lights in there. I had bought the Harbor Freight head flashlight and mounted it inside the lid. That worked till I hit a good bump. The next time I opened the trunk, the light was in one corner and the batteries were all over. That was the end of that. I looked but couldn't find the OEM fixture that Honda must have made at some point. Inside the trunk lid, under the inside cover, there are a pair of two pin connectors. According to the service manual they are intended for lighting the inside of the trunk. The picture to the right is the final product. I'm not plugging WingStuff, it came with the bike.

Not including time, total cost was about $20. Thats based on a well stocked junk drawer.

|

|

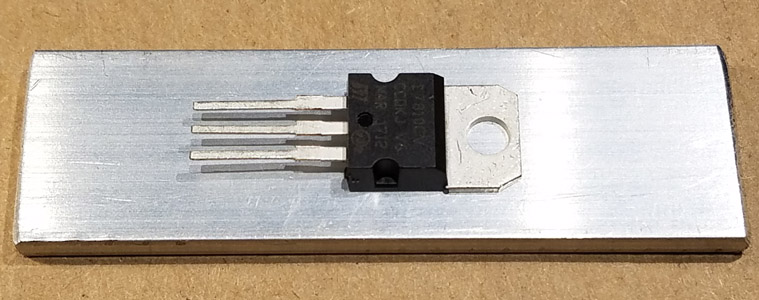

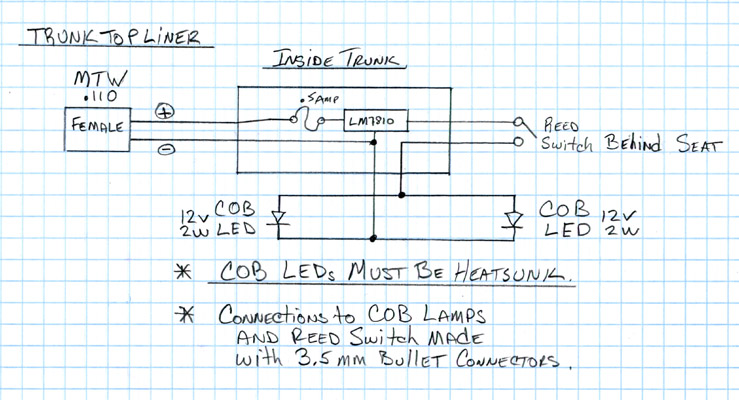

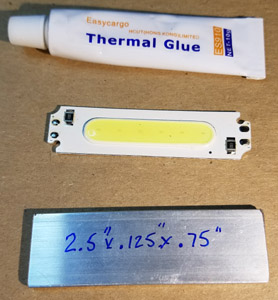

After searching the web for assembled lights and not finding what I wanted. I stumbled on the COB type strip LED. There are many Ebay vendors that sell the 60mm x 5mm 12 volt 2 watt version. I bought 5 for less than a dollar each with free shipping. The catch to these is that they NEED heatsinking. The small aluminum backing ins't enough to keep it from burning up. Temps were over 140 F ! A couple of things can be done to easily get the heat issue under control. The first is to use a heat transfer glue to attach the strip to a section of aluminum stock. Home Depot sells .75" x .125" x 36" for under $10. Cutting the stock into smaller lengths of 2.5" is easily done with a hack saw and a steady hand. Adding the aluminum gets the temp to just under 120 degrees F. Which is hot, but not melting plastic hot. The COB lights will get mounted to the far left and right sides of the trunk as high up on the side wall as I can get them. That way, they are "invisible" standing behind the trunk. Adding heat shrink to the ends of the heat sinks helps prevent possible shorts. |

||||||||||||||||

|

||||||||||||||||||

.

|

||||||||||||||||||