How to get started using CAD/CAM tools!

If your like me you probably enjoyed drawing and making useable stuff in your dad's garage. On a weekend, I would grab the saw horses out from the garage, get the tape measure and shop tools to cut the plywood. And the good ol' hammer and some nails was how I got many weekend projects done back in the day.. But never in my wildest dreams did I ever expect that I would be using a laptop computer to build out entire projects in a virtual 3D world from start to finish. And then have secondary computers manufacture these parts I had just designed. Modern CAD/CAM software has totally revolutionized the way we work in some amazing new ways. I find these new tools to be pretty amazing and I am still learning the ropes myself. But all I can say is if you like to build stuff in the garage or enjoy designing things... then Computer Aided Design Software is totally for you! I'll offer up some of my quick tips to help anyone get started in CAD below:

TIP #1 GET EDUCATED ! Your first step is to educate yourself with CAD software Visit the local public library and begin to search for possible books or videos on the subject of 3D printing and CAD design. Study that material cover to cover! Use the internet for locating additional helpful videos and material to further your education with CAD/CAM. Youtube CAD tutorials are pretty good. Also try and visit any trade & community colleges or local skill centers that can offer up additional training. Remember, the more skills you acquire with the craft of 3D Printing and CAD design... the better off you will be to start making your own parts successfully.

TIP #2. GET THE TOOLS ! Be smart. Select the CAD software that works best for your needs and budget. I have found you do not have to spend a fortune to get decent results if your willing to learn about the various free or low cost software options and cad tools. Don't ever give up your rights at the whims of software developers who severely limit your designs or push you towards expensive monthly plans. All of that is bull.

TIP #3. BE PATIENT ! Remember the fact that your learning completely new computer skills and methods, learning CAD takes time. Keep at it. Don't get frustrated. The World needs good CAD designers and you could be one of them! Practice! Practice! is our motto!

Remember! If you have just a small run of parts that need to be printed or manufactured. It might be better for you to just outsource that detail to a 3rd party vendor or friend. I have had good luck with 3D print companies like Shapeways or you may find a local fabricator to help you at: https://100kgarages.com/

A great place to help you build your first ham radio project with electrical circuits with STEM is to visit: https://www.tinkercad.com/

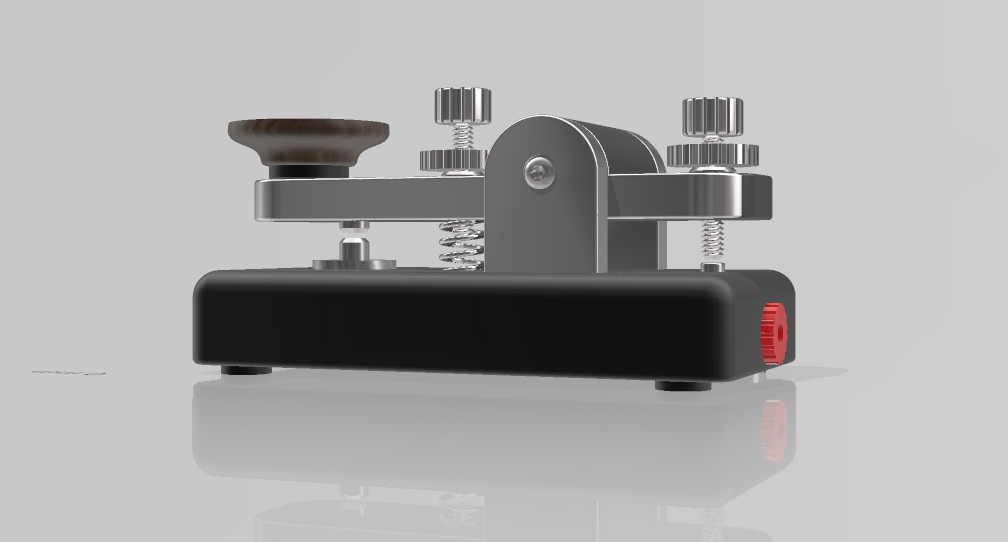

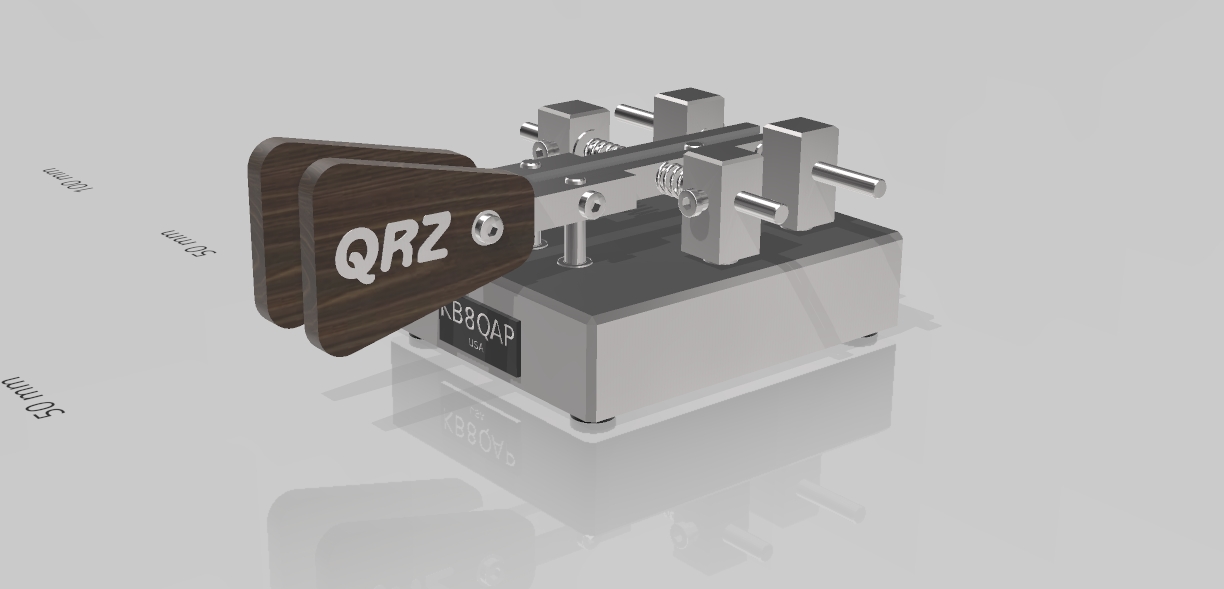

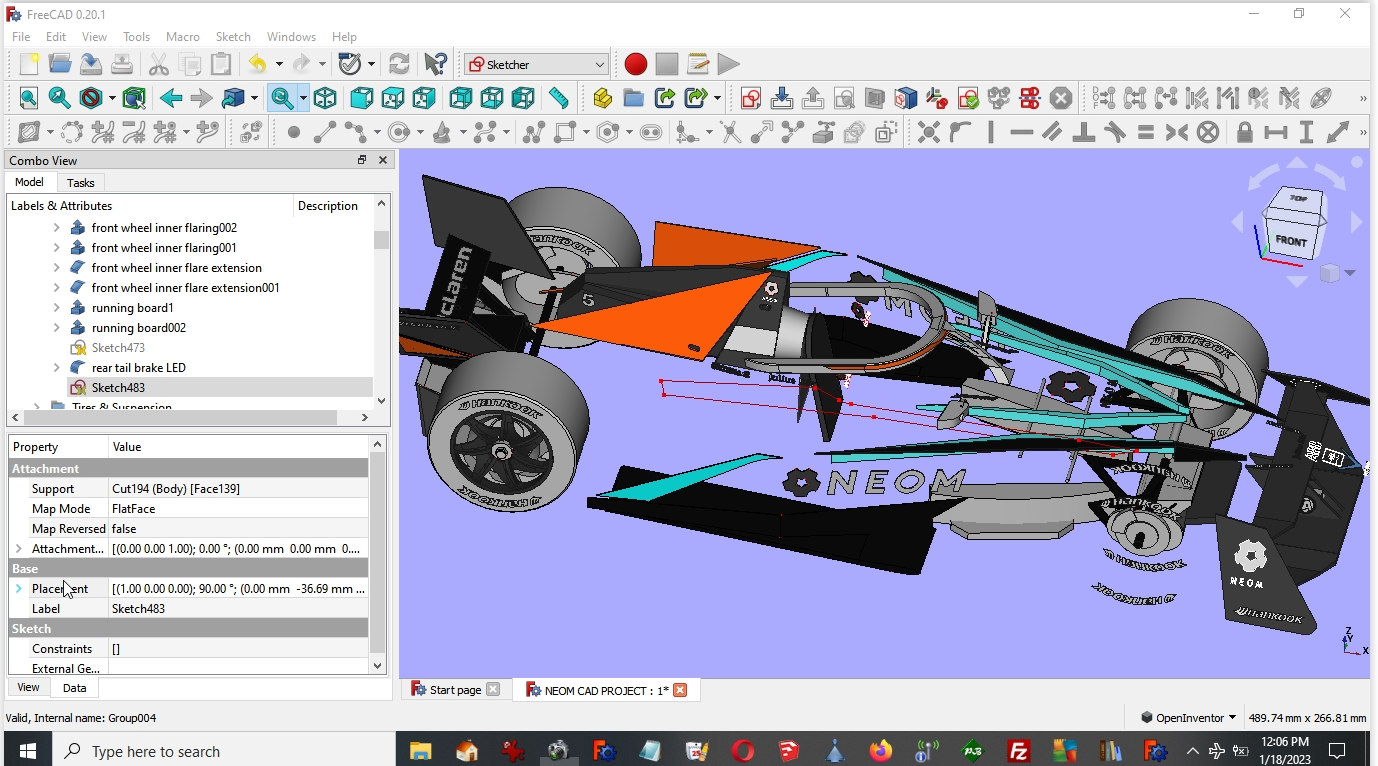

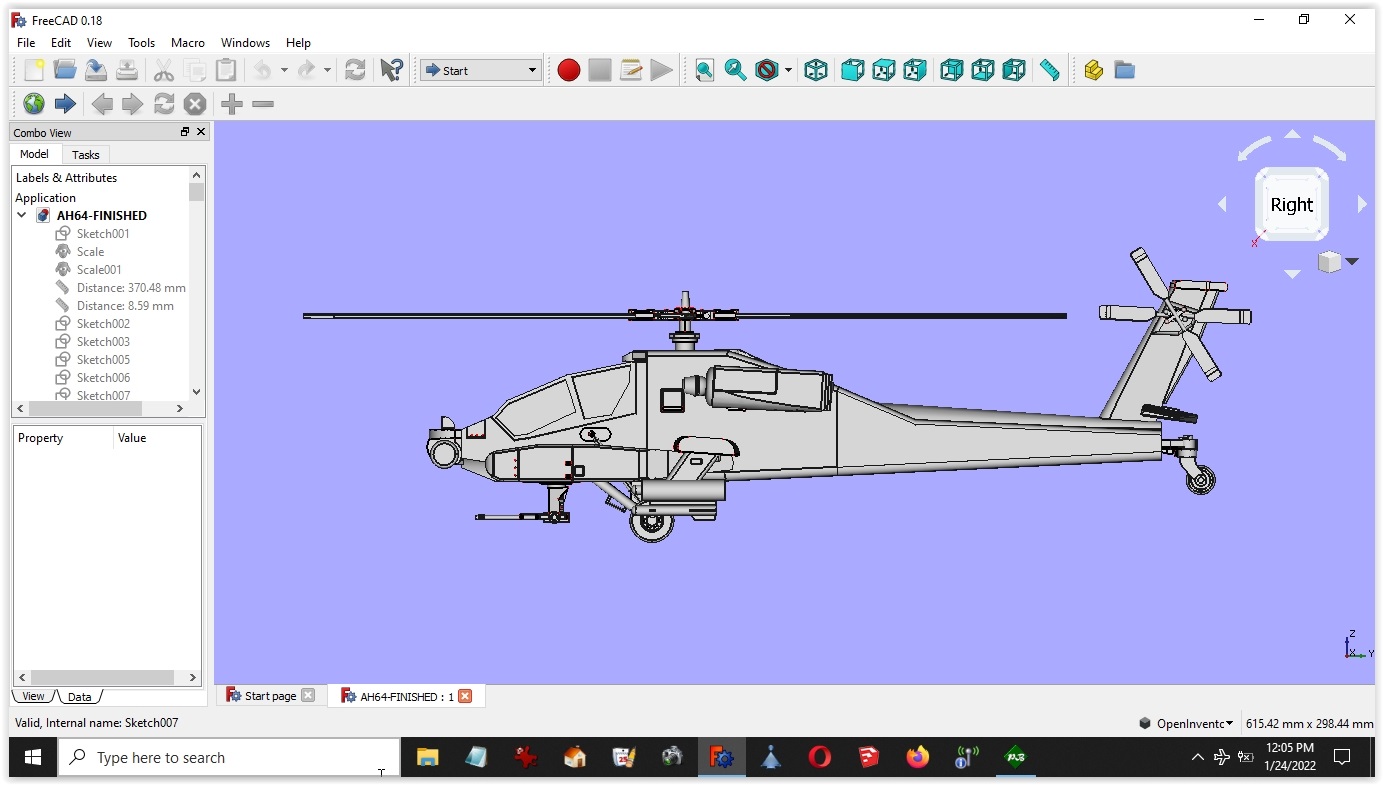

The CAD software I use often for the bulk of my scale model work and a few amateur radio projects is called " FreeCAD". And as it's name suggests it is totally FREE! and open source CAD. It's innovative tools and powerful work benches are used across the globe by artisans, engineers, architects, machinists, and designers. The softwware is available for download compatible with APPLE MAC, LINUX, or WINDOWS (64bit) computers. With new build releases every 9 months or so. Learn more at : https://www.freecad.org/

FreeCAD may not be best for newbies. But it's developers have really helped smooth out the learning curve with it's software by providing a good help forum to post user questions at the following wiki at : https://wiki.freecadweb.org/Getting_started

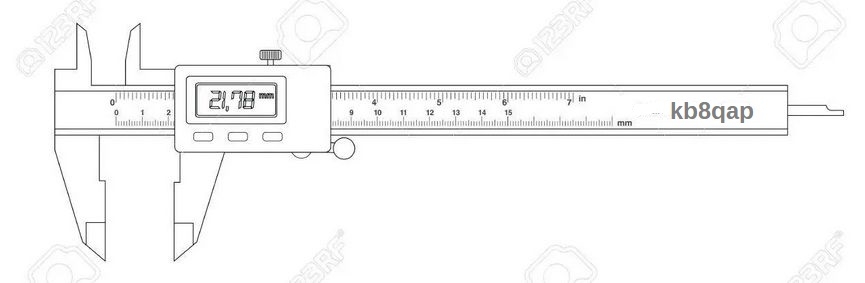

To help with the dimensional accuracy of your CAD models, I recommend using the inexpensive stainless steel digital calipers from Harbor Freight, I find them pretty useful for taking part measurements both in Standard or Metric on the bulk of smaller parts I work with and need to spec out. They are modestly priced and very accurate. The digital calipers are available at : https://www.harborfreight.com/4-in-digital-caliper-63710.html

Lastly, FreeCad is a solid based modeling program that allows your projects to be exported out to (CAM) computer aided manufacture. Meaning the virtual 3D models you design or import into the software can be later interpreted with G code for CNC machines and 3D printers. FreeCAD also leaves your model designs fully parametric giving you the freedom to make revisions to your virtual 3D models more easily.

Hopefully with these 3 quick starter tips at hand and providing a few links to the types of software and measuring tools I use will help inspire a few of you to try your hand at CAD/CAM for your next radio project.

Thanks for reading & Keep designing! J.

|

![]()