ICOM 746 and 746Pro

LCD Back Light

and Dead Transmitter Repair

Dave Sparks, KV5A

The

ICOM 746Pro has two well known problems. The LCD display back light

driver transistor will eventually dissipate way too much heat and fail.

In the worst case, the result is a carbonized PC board and

lifted

mounting pads. Your display goes dark. You can live without it but the

display is almost impossible to see in a low light environment. The

other issue is the sudden death of your transmitter. That

means

your backup transceiver will have to take up the slack while your 746

rig is off the the repair facility. Doing the repair yourself will save

you a bunch of time and money but do this only if you can work with

small SMD components and have the proper tools to do so. There are

several solutions published on line by hams who have had these

failures. You can decide if their solutions meet your

requirements. Mark, K5LXP, has a very informative article at the link

below.

Mark provides details for this repair I will not duplicate

here.

http://www.qsl.net/k5lxp/projects/746Pro/746ProNoTX.html

Ed, WA3WJS provides this intuitive article at

this link

below.

https://wa3wsj.homestead.com/IC-746Pro_Sudeden__Death_Fixes.pdf

The

following is my analysis and the repair I decided to do. I do not

guarantee your results if you attempt to duplicate my repairs but I

think you will find it is a thoughtful approach.

The 746/Pro

Sudden Transmitter Death

My

research of all the posts I read indicates there may be several

possible causes of the failure of RF transmit driver IC-151, uPC1678G.

Among them are ESD, excessive heat dissipation, and a high voltage

spike on the 5 volt supply line. All of these possibilities

are

plausible. The failures seem to occur over various periods of time and

under different circumstances making it difficult to pin down the exact

cause. Ed, WA3WSJ, posted an article on this issue. I was

convinced he was on to something. In short, he had a friend whose

coworker had a problem with a similar circuit design. He kept blowing a

like RF IC chip trying to get it to work, but why? The reason

discovered was that the manufacturer's design called for a nanoHenry

choke in the 5V supply line and not a uHenry choke. Thus, every time

the power supply was turned on the chip's collector output was hit with

a large inductive spike eventually blowing it out. Replacing the choke

with a smaller choke did the trick and the circuit worked just fine. If

heat dissipation is not the issue then adding a heat sink is not

necessary. So, with that in mind, instead of

duplicating

other repairs, I approached the repair as follows.

⦁

1. Replace IC-151 with a new uPC1678G available

from Circuitstransistors.com. $4.00 each plus shipping as of

May 1, 2018.

⦁

2. Replace C156 .0047 uf chip cap with a 20uf chip cap. (or two 10 uf

caps, DigiKey part number 445-11219-1-ND) This will filter

the

Vcc chip supply and eliminate any excessive inductive spike to the chip

output collector. This is likely the only modification really necessary.

⦁

3. Lift R157 10 ohm resistor from the +5.0 volt supply, stand it on end

attached to the pad nearest IC pin 8. Connect the anode end of a 2.7

volt zener (DigiKey part number 1N5223BCT-ND) to the lifted end of R157

and solder the cathode end to the transmit 8 volt line at R156 330 ohm

resistor. This will supply power to the chip only on transmit. This

might not be necessary but it does no harm.

⦁

4. Add a 1 mH choke (DigiKey part number RLB0608-102K-ND) to

the

center pin of the HRX connector (J1) and the PCB ground plane. This is

for added ESD protection. K5LXP suggests this and it too

does no

harm. Time will tell if my solution will hold up. So far so good.

Figure 1.

This is the ICOM 746Pro RF Unit PC Board where the driver chip circuit

is found. IC-151 is located on the left side.

Figure 2.

Close

up of the new uPC1678G chip installed and two 10 uF caps stacked to

replace C-156. Also shown is a 2.7 volt zener attached to the 8 volt

transmit supply line.

Figure 3.

A

1 mH choke is installed on the bottom of the board for added ESD

protection. The pin diodes were factory installed and were not changed.

Figure 4.

While

I had the radio opened up, I added the optional the CR-338 High

Stability Crystal Unit to the same board. This provides better

frequency stability and accuracy especially noticeable on 6 and 2

meters.

746

LCD Back Light

The

LCD back light issue eventually plagues every 746Pro. I bought my rig

at

a tailgate a few years ago and it was not long till the intermittent

back light on again and off again symptom appeared. Eventually it

stopped working all together and I lived with it for a long time. Now

is the time to get my back light back. The common cause of this failure

is excessive heat dissipation in the high voltage driver transistor,

especially when the brightness is set to less than 100%. The transistor

dissipates more power at lower brightness settings contributing to the

failure. The root cause is of course a very poor ICOM design.

KA1MDA has a very informative and detailed article here:

http://www.ka1mda.org/ham/homebrew/746/index.htm

Several

of the repairs I found on the WEB included adding a heat sink inside

the shield cage and that is ok, but the heat sink was not attached to

the tab of Q302 in any of these repairs. It was maybe touching the

plastic case because of the mechanical implementation. This was not

very effective in my opinion. The transistor tab is where the heat sink

needs to be attached to effectively cool the transistor

junction.

So, I decided to take a different approach.

I ordered more than one

of each part replaced just in case, well just in case... and then

thought about what I needed to do. Parts are available from DigiKey.

Direct replacements are Q302, 2SB1201-TL-E, C-303, EEE-1CA470SP, Cap

Alum 10uf, 20% 16V SMD, and C302, EEE-1CA100SR, Cap Alum 10uf 20% 16V

SMD. All the other parts came from my junk box. The copper

plate

is .0675" thick cut to fit inside the shield less about 1/16"all around

so as to not touch the PCB or the shield. The fiber shoulder washer

fits into a 1/4" hole in the shield. The mounting screw is 4-40 cut to

length to fit the thickness of the shield, cooper plate and the little

IC heat sink plus a few threads for the nut. The silicone insulator is

a strip cut to size from a silicone rubber oven glove available from

many grocery or kitchen supply stores. The material used is .052 "

thick. You might even have one at home already. The thermal

compound

and all the tools or other material to fabricate my heat sink assembly

were on hand.

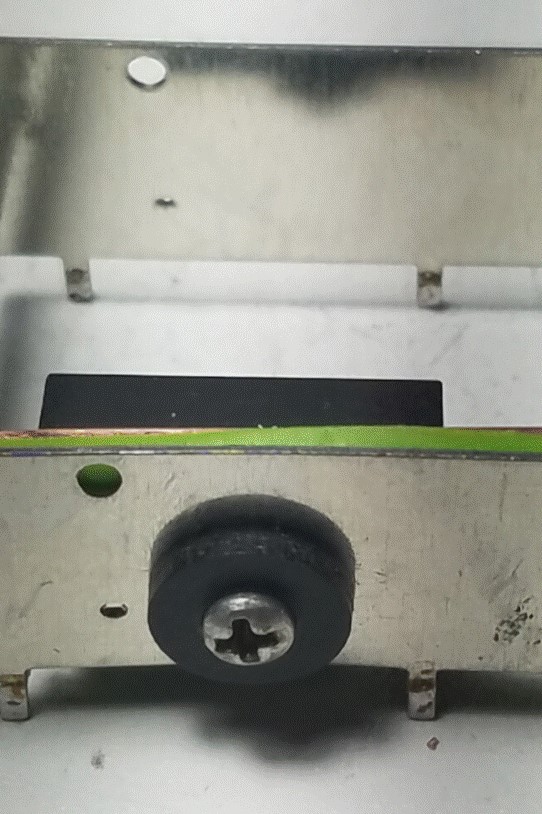

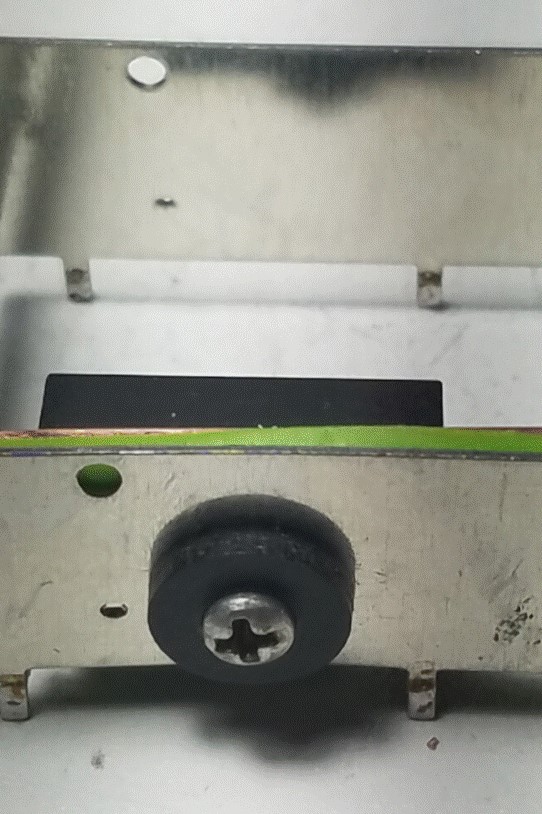

Figure 5.

This

is the back of the front panel as removed from the body of the 746Pro.

The ribbon cables and connectors must be disconnected and the the

mounting screws are removed in order to carefully separate this board

from the remaining front panel circuitry. There are two pot mounting

nuts that also must be removed.

Here is a video detailing the disassembly of the front

panel.

https://www.youtube.com/watch?v=3JWFYIl3zTc

Figure 6.

The

defective Q302, 2SB1201, is shown here in the bottom right of the

shield. The PC board shows discoloration due to excessive heat.

Figure 7.

The

transistor and associated capacitors were removed. The pads where

Q302 was

soldered lifted from the PCB. The PCB is burned and the surrounding

area is discolored. I scraped as much of

the carbon off the board as possible. The shield around the components

was removed to effect the repair.

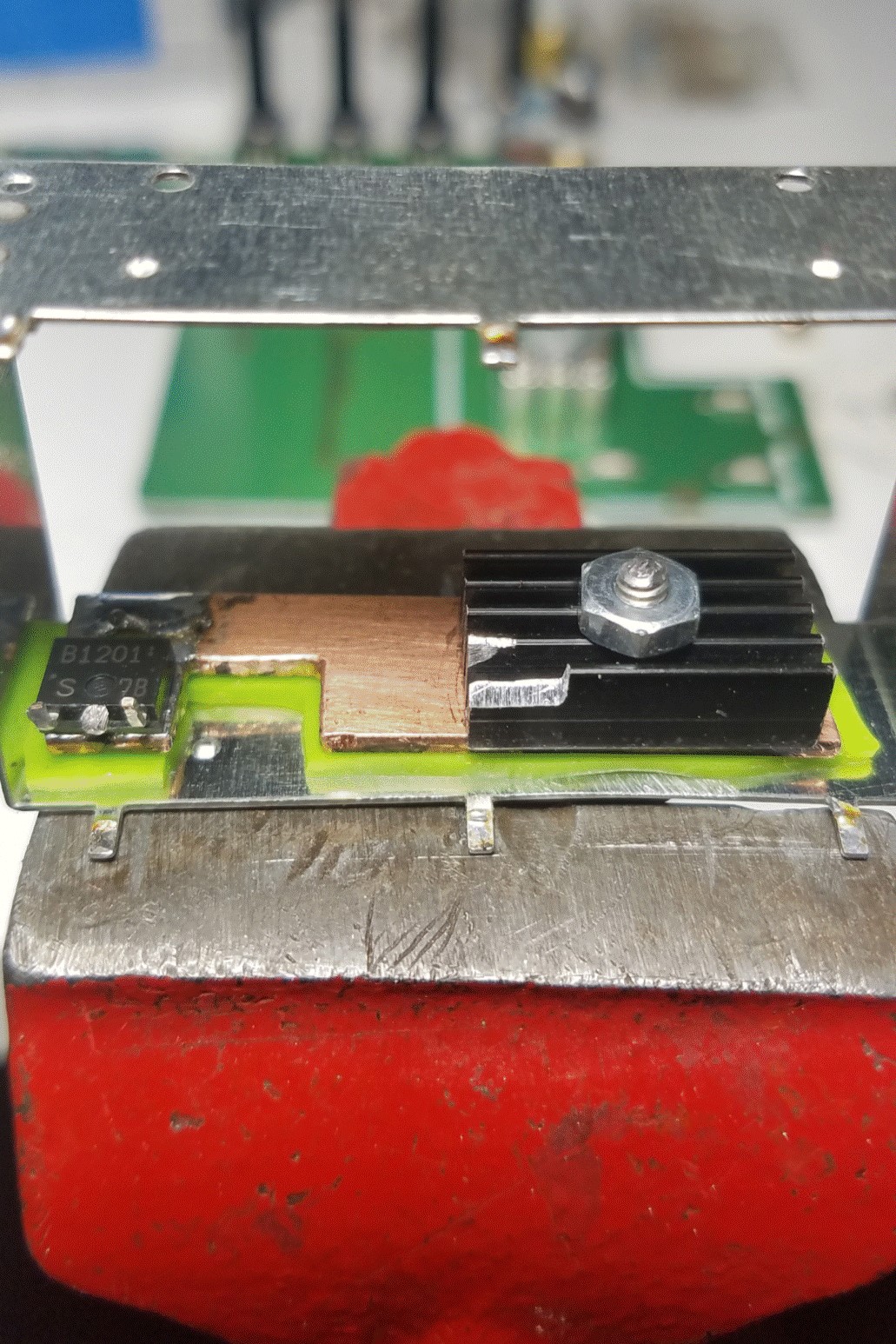

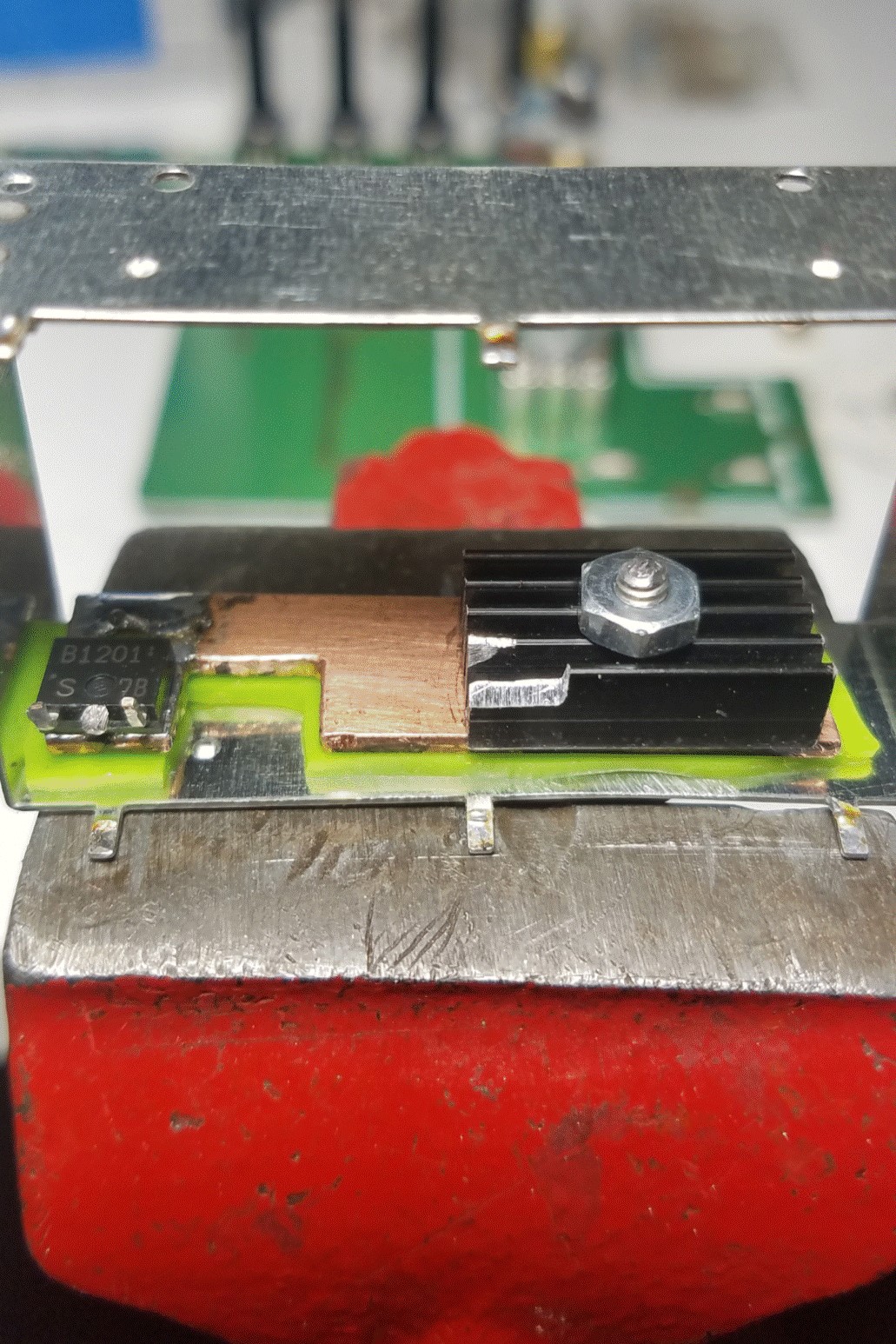

Figure 8.

Since

there is no way to secure the transistor to the PCB as in the original

design, I chose to mount the transistor vertically and attach a heat

sink directly to the transistor tab. The copper sheet shown here is

slightly more thick

than a penny. Notice the cut out for clearance of

C-302, 10uf cap. Both (C-303) 47uf, and (C-302) 10uf,

capacitors are

replaced in case they were damaged.

![]()

Figure 9.

The

heat sink must be insulated from the shield since the collector is at a

high voltage potential. I used a small strip of material from

a green colored silicon oven glove. It is a good heat and electrical

insulator. I

added a small IC heat sink for added radiation of the heat. The

assembly is mounded to the inside of the cage with a 4-40 screw and a

fiber shoulder washer on the outside of the cage. Thermal grease is

applied between the copper and the black heat sink.

Figure 10.

Q302

is solidly soldered to the copper sheet. A small amount of the black

heat sink is filed away to clear a nearby transistor. The legs of

transistor Q302 are bent up to enable adding #30 wire wrap wire to make

the connections to the PCB.

Figure 11.

The

heat sink assembly is mounted to the shield, and Q302 connections are

soldered to the proper points on the PCB with #30 wire wrap

wire.

Red nail polish is painted on the board to cover an area of exposed

ground plane and to provide mechanical stability for a loose trace on

the PCB. A small piece of the silicone material is between the PCB and

Q302 legs to insulate it from the near by ground plane.

Figure 12.

I

drilled several holes in the shield lid just above the black heat sink

to facilitate the escape of radiated heat. An additional piece of the

silicone insulator was glued inside the lid just above Q302 as mounted

to prevent the copper sheet from possible contact with the lid. The

mounting screw is tightened enough to prevent rotation of the heat sink

assembly within the shield. I applied locktite to the 4-40

screw

threads during assembly. With the silicone in place at the top and

bottom of Q302 the heat sink will stay in place.

Figure 13.

The

PCB is now re-attached to the front panel assembly. The mounting screw

head on the shield is very close to the encoder body though it is not

touching. For added protection, I put a piece of electrical tape on the

encoder body just in case anything moves. If you look carefully you can

see the black shoulder washer on the outside of the shield.

The head of

the screw could be filed down

for greater clearance but I did not think it was necessary,

but that

depends on the particular hardware used in any case.

Figure 15.

After

a careful re-assembly of the front panel and installing the top and

bottom

cover back on the radio, I'm ready for the the smoke test. Holy Cow!

The display is fixed and the transmitter is back to full output power.

The transmitter is working like new too. Happy days are here

again!

Parts are available from DigiKey for the Back Light

repair. Direct replacements are Q302, 2SB1201-TL-E, C-303,

EEE-1CA470SP, Cap Alum 10uf, 20% 16V SMD, and C302, EEE-1CA100SR, Cap

Alum 10uf 20% 16V SMD. All the other parts came from my

junk box.

The copper plate is .0675" thick cut to fit inside the shield less

about 1/16"or more all around so as to not touch the PCB or the shield.

The fiber shoulder washer fits into a 1/4" hole in the shield. The

mounting screw is size 4-40 cut to length to fit the total thickness of

the shield, cooper plate, silicone insulator, and the little IC heat

sink plus a few threads for the nut. The silicone insulator is a strip

cut to size from a silicone rubber oven glove available from a grocery

or kitchen supply store. The material I used is .062" thick. The

thermal compound, other supplies and all the tools to perform this

repair were on hand. Thanks to K5LXP, WA3WSJ, KA1MDA and many

others for their contribution to the understanding of these problems

and their take on subsequent repairs.

Now on to the next project.

If you have comments or questions please email.

73, KV5A, Dave

[email protected]