Modifications for the Kenwood

TM-731

19-07-1998 TM-731 frequency and cross band

repeater

The TM-731a will transcive between 136-174 MHz and

400-500 MHz as well as perform cross band repeter function when the following

modifications are performed.

- Remove both the top and bottom cover. Disassemble the front panel such

that the control unit (X53-3250-XX) is accessable.

- Remove R121, R123 and R25. While R125 snd R124 must be present.

- If the time-out timer function is not desired, remouve R122 as well.

- Reassemble the unit and perform a microprocessor reset before operating

the set.

- Preserve your license by operating whithin the bands it is cover for.

19-07-1998 TM731 & 9600

Bps

The TM731 is different enought to cause problems.

What

need to be done is to add another RX Mute transistor. (look the schematics and

see how the TX deviation is shorted to ground during receive.)

Use a

plain NPN and a pair of 10k resistor (copy the one used on VR3 in the

schematics.)

Take the TX DATA and feed it to the collector through a

series 1k resistor, and then feed that through another 1k resistor to the wiper

on the deviator pot.

This was a result of Kenwood changing the deviation pot

value from 10k to 100k (it's wasn't broken, but they fixed it anyway.) It is

full of surface mount devices.

Article of Jeff WA6FWI @

WB6YMH.#SOCA.CA

From: CQ USA - June/92

19-07-1998 TM-731 fuer 9600

Baud

de DG5EM @ DB0IZ

Umbaumassnahmen beim TM 731

von Kenwood zum betrieb mit G3RUH-Modem 9600 Baud

Das Geraet von der

Seite oben die Platte abschrauben, wo sich auf dem rueckseitigen Kuehlkoerper

die Blindbuchse mit Stopfen befindet.

Kontrollieren ob man wirklich die

430er-UNIT vor sich hat hi.

Diesen Stopfen entfernen und das Loch als

Eingang fuer das 4-Ader abgeschirmte Tonkabel benutzen. (Zugentlasstung nicht

vergessen!) Von dem Einbau einer Klinkenbuchse oder aehnlichen rate ich ab,

besser ist es aussen eine Steckverbindung vorzusehen, um den TRX vom Modem zu

trennen.

Sollte sich das Tonkabel nun im TRX befinden und die Adern sind

abisoliert, kann der Loetkolben angeschmissen werden.

Die Leitung

RX-Audio vom G3RUH-Modem an Pin 9 von IC3 (MC3361/SMD) loeten. (feine Spitze ist

beim Loetkolben angesagt).

Nun schaut man auf eine 4polige Steckerleiste,

die im Schaltplan als Nr.12 angegeben ist.Die vierte Ader davon hat die

Bezeichnung MDI.

Sie verbindet den Mikrofonverstaerker-Ausgang mit dem

Hubpoti VR3. Diese Ader wird jetzt aufgetrennt und ein 12V-Reed-Relais Oeffner-

Kontakt dazwischen gesetzt.(Das anbringen des Relais muss jeder selber

austueffteln da in erster Linie von der Bauform abhaengig) An der Relaisspule

nun eine der restlichen 3 Adern des Tonkabels anloeten ,spaeter wird ueber diese

Ader 12V vom Modem kommend herangefuehrt.Also....Modem eingeschaltet =

Paket

Modem ausgeschaltet = Phonie

Die Leitung TX-Audio vom

G3RUH-Modem an das heisse Ende loeten, also in Richtung dem Hubpoti VR3

gesehen.

***auf KEINEM Fall am Hubpoti im TRX eine Einstellung

vornehmen!***

Der Hub wird ausschliesslich am G3RUH-Modem

bestimmt.

Das anloeten der letzten verbliebenen Ader, der PTT-Leitung,

ist schon etwas umstaendlicher.Schliesslich muss man irgendwie an die

Mikrofonbuchse von hinter her dran.

Wer nicht die Lust hat alles weiter zu

zerlegen, kann auch wie bisher die PTT vorne per Stecker anschliessen.

Von

innen her ist es allerdings eleganter, da das Mikro dranbleiben kann und die

laestige umstoepselei umgangen wird.

An dieser Stelle sei dringend

erwaehnt, das nur gutes Tonkabel verwendung finden sollte, mit DICHTER

Abschirmung.

Eine gute Kontaktgabe mit der Geraetemasse ist entscheidend fuer

ein sauberes Sende-und Empfangssignal.

HINWEISE:

Mikmiken wie das

einfuegen von einem zusaetzlichen Relais fuer ZU - und ABschalten der Sende-NF

sind NICHT noetig und auch garnicht wuenschenswert.Das TXD wuerde doch negativ

darunter leiden. Die NF-Abschaltung uebernimmt der spezielle Schalttransistor

Q18.

Er ist in der Lage im Empfangsfall die Sende-NF vom G3RUH sicher zu

unterdruecken (nach Masse zu ziehen).

Ansonsten waere es auch garnicht

moeglich ein empfangenes Signal richtig zu decodieren (gaebe nur

Mischprodukte).

Der 455khz-Filter CF1, brauchte bisher nie gegen einen

breiteren getauscht werden.

Zum Abgleich ist nur zu erwaehnen, das der

Sende-NF-Hub vom Modem so klein als moeglich gehalten wird.Das kommt der PLL

sehr zu gute (Regelneigung ist kleiner) und schont das Bandraster.

Als

Faustformel hat sich erwiesen das der Hub "gut" ist, wenn er sich mit dem

Grundrauschen auf einer Ebene befindet.

Kann mit 2ten TRX oder Hilfe von

einem anderen OM schnell eingestellt werden.

TXD unter 11 ist moeglich

und sollte auch !darunter! betrieben werden, da bei einem 96er-Einstieg ein zu

hohes TXD die Suppe versalzen kann.

Schwierigkeiten sind nur bekannt

gworden bei betrieb ueber einen Duplex-Digi.Manche Exemplare rasten wohl bei

grosser QRG-Aenderung nicht rechtzeitig ein und HOEREN dadurch extrem zu

SPAET!

Ich habe diese Anleitung jetzt mal veroeffentlicht, da nun genug

Erfahrung mit diesem PLL-Mobil-TRX in bezug auf 9600bd gemacht sind.

Als

Abschluss moechte ich dennoch ausdruecklich betonen, das die Verwendung von

PLL-Geraeten NICHT auf Dauer zu empfehlen ist. Es ist nur eine Frage der Zeit

bis die neueren Digi,s (96er sind gemeint) auf wesentliche schnellere Parameter

eingestellt werden.

Ich selber benutze einen IC475E von Icom, der fast

wie geschaffen ist fuer diesen betrieb (ueber diesen TRX hab ich schonmal was

veroeffentlicht).

vermutlich sind mir bei dieser Beschreibung ein paar

Fehler unterlaufen (oder doch diesesmal nicht)?

Fragen zu diesem Thema

und Erfolgsmeldungen bitte zu richten an

DG5EM , Helmut @

DB0IZ

19-07-1998 TM-731A

Hooking to TNCS

Marty Goodman KC6YKC

June 1992

Home packet BBS: WD6CMU Richmond, Northern

CA

I recently acquired both a PK88 TNC and a Kenwood 731a dual band

mobile transceiver. I wanted to hook the Kenwood to the PK88. What I found was

that the audio output on pin 6 of the eight pin microphone connector on the

front panel was not the same as the audio that comes out of the speaker or out

of the rear speaker connector.

What you get out the audio from the front

panel mic connector on pin 6 is an UNSQUELCHED audio. Kenwood does this,

apparantly, to support their RC10 remote controller for the unit, to allow the

RC10 independent control over the squelch on the audio at the RC10's speaker.

This causes a problem, for when you feed that into the audio input of the PK88,

its DCD light stays on ALL THE TIME. The PK88 will receive data just fine when

hooked to pin 6 of the TM731a mike connector, but it will refuse to key the

transmitter because it perpetually thinks the air is "busy".

The simple

approach to hooking the PK232 to the Kenwood involves using a separate cable

with a 1/8 in mini phono plug at each end, and run that between the audio phono

connector on the PK88 and the speaker output jack for "main audio" on the

TM731a. This will allow packet operation, and is no doubt the approach that

virtually everyone uses. There are some drawbacks to this arrangement,

tho.

Using two cables is a tad clumsey. Worse, when you plug in the cable

in the rear speaker connector, there is no way to enable the speaker to audibly

check your signal. It also makes it impossible to make a switch box to switch

the TM731a from packet to audio operation at the flick of a switch, for as long

as the phono plug is plugged into the back of the TM731a, you CAN NOT enable its

internal speaker. Finally, this arrangement requires you to adjust the volume

control to the right level and leave it there.

What follows is a mod that

give you a SQUELCHED, LINE LEVEL audio signal available on pin 6 of the

microphone connector. With such an arrangement, you can turn your speaker volume

up and down as you like, and it will not affect the audio going to the packet

box. You can use a single cable to connect the packet box to the transceiver,

and it is easy to rig up a switch box that switches between the packet box and

the hand microphone. The only disadvantage of doing this mod is that your TM731a

will NO LONGER be compatible with the RC10 remote control device.

The

Modification:

This modification requires skill at fine soldering, a good

ultra fine-tipped pencil type soldering iron, and a short piece of 28 gauge

stranded wire. You really should have at hand a Kenwood service manual for this

rig, with complete schematic and board layout diagrams, before you attempt it,

tho I HAVE tried to write my description so that you can do the mod without a

service manual at hand.

- Turn off power and disconnect the rig from its source of power

- Remove the BOTTOM cover of the rig.

- Lay the rig on your work table with the front panel pointing away from

you, and its rear heat sink pointing toward you. On the right will be the main

volume and squelch control. Look at the little connectors that hook the front

panel of the radio to the board you have exposed and are looking at. On the

extreme left is one connector with eight pins in a row, with the third pin

from the left unused. To the right of that is a five pin connector with the

middle pin not used. To the right of that connector is an electrolytic

capacitor, to the right of the cap is a two pin connector, and to the right of

the two pin connector is a phillips screw that is one of the screws that hold

the board you are looking at inside the rig.

Locate that five pin

connector mentioned above, the one that has its middle pin unused. The SECOND

WIRE from the LEFT of that connector should be a RED wire. That spot on the

connector will be labelled on the main board you are looking at as "RDM".

- CUT this red wire about three quarters of an inch from where it leaves the

connector. Tape up the portion that goes to the connector.

- Strip off about a quarter inch of insulation from the portion of the red

wire that dives into the rig and heads toward the front panel.

- Locate "IC 8" on the radio. This is actually NOT a real integrated

circuit, but rather is one of six little vertical circuit boards that jut up

like fins from the main board. IC 8 is the left most of the six such boards,

and is right next to IC 9, which is a zig zag in line pin integrated circuit.

IC 8 is located just toward you from the five pin connector with the four

wires... the one from which you cut the red wire. IC 8 is labelled as "IC 8"

in silk screening on the circuit board.

- Solder a short length (2 or three inches) of stranded, insulated, 28 gauge

wire to pin 9 of IC 8. Pin 9 of IC 8 is the next to last pin of this single in

line pin "IC". The "last" pin of IC 8, or pin 10, is located closest to the

rear of the rig (closest to you, given the orientation of the rig that I

suggested).

- Now solder the other end of this wire to the stripped, cut portion of the

red wire that you prepared in step 5 above.

That's it! you now have

modified your rig to provide line level, squelched audio on pin 6 of the

microphone connector.

For those technically inclined, you should note that

this audio is leaving an audio amplifier, and going thru both a 1K ohm resistor

and a .1 mfd capacitor before it arrives on pin 6 of the microphone connector.

Thus the signal is DC-blocked and reasonably protected against minor nastiness

that might appear on pin 6.

I'd appreciate any feedback from those

attempting this modification, tho of course I must note I cannot take

responsibility for any harm that may come to your radio due to either proper or

improper implimentation of this modification. I CAN say honestly that I HAVE

done this to my radio, and it appears to work quite well.

19-07-1998 Kenwood Cross Band Repeat: How to

USE it

Hardware information for modifying the Kenwood TM-731A for

cross band repeat is widely available on many packet bulletin boards. However,

information on how to impliment cross band repeat is often not present along

with the description of the hardware mods. What follows is KENWOOD's

documentation on how to USE the TM731a after it has been modified for cross band

repeat:

Text of Kenwood Sheet on using Cross Band Repeat on the

TM-731A:

The repeater corss-band operation allows the TM-731A to receive

on one band and re-tramsmit the signal on the other band. An incoming signal

will automatically be switched to the sub-band. The TM731A will then re-transmit

the signal from the main band. Each band may contain shift information. Only one

band can contain sub audible tone information (the optional TSU-6 ... currently

called by Kenwood the KQT8... is required for tone decode). If one band requires

a sub-audible tone, either select the TONE function for encode or the CTCSS

function for encode / decode. DO NOT turn both TONE and CTCSS on in the one

band.

- Select the first frequency in the main band. If required, select the

offset.

- Press the BAND key to move the contents of the main display to the

sub-display.

- Now select the second frequency and offset.

- If Tone or CTCSS is required for one of the bands, continue with this

step. If Tone or CTCSS is not required, go to step 5.

- Place the operating frequency that requirs TONE or CTCSS in the main

band (use the BAND key).

- Select the sub-audible tone by pressing the F key and then the T.SEL

key. Rotate the main encoder knob until the desired tone is displayed. Press

any front panel key to display the operating frequency.

- If only the TONE function is required, press the TONE key (the [T]

indicator will light in the display).

- If the CTCSS function is required, do not turn the TONE function on.

Instead, press the F key and then the CTCSS key (the [CTCSS] indicator will

light in the display. If the CTCSS arrow is not pointing towards the main

display, press the F key and then press the CTCSS SEL key.

- Adjust the main and sub-band squelch controls to the threshold point. The

TM-731A will transmit in the repeater cross band mode if the squelch controls

are set too low or a signal is received. (comment: setting both squelch

controls properly is VERY important!)

- Note:

The next step will place the unit in the repeater cross-band

mode

Press the F key and then press the A.B.C. key. Three dots should

be lit in both display frequencies. The unit will now operate as a cross band

repeater as described above.

- To take the TM-731A out of the cross-band repeat mode, repeat step 6.

19-07-1998 Kenwood TM-731A firmware

bug

The Kenwood TM731A dual bander has a firmware bug that breaks

the 2m VFO scanner in certain circumstances, that is, the 2m VFO scanner won't

work properly if certain PL tones are stored into memory 1. So far, all tested

731A's have had this problem. The highest serial number tested was 72713. To

demonstrate the problem, perform this experiment:

- If not already done, load search bounds into memories A and B of the 2m

unit. Verify that the VFO scanner works.

- Change the PL tone for memory 1 to (for example) 91.5: select memory 1,

press F VFO to transfer it to the VFO, then press F TSEL and select 91.5 Hz PL

tone, then store back into memory 1 by pressing F MR.

- Set the VFO to a frequency outside the range given in memories A and B,

then start the VFO scanning (by pressing VFO for a few seconds).

- If your radio has the bug, it will alternate between the frequencies

stored in memories A and B. If you start the scan while the VFO is within the

search range, it will scan up until the top limit is reached, then begin

alternating between the two limit frequencies.

- To restore 2m VFO scanning, program memory 1 with one of the several PL

tones acceptable ... the default of 88.5 Hz works fine.

- The 70cm unit does not appear to have this problem.

21-04-2000 TM-631/731A Memory loss

modification

Author: Kenwood

Communication, inc.

Service Bulletin no. 972 (8-8-1990)

Some TM-631/731A owners have reported that the transceiver intermittently

loses its memory channel information when the power switch is turned on. The

following modification will absorb pulses on the CPU interrupt line (INT4) and

reconfigure the backup switching circuit to avoid unintentional memory loss.

Read all instructions before proceeding. Do not attempt this modification if

it is beyond your capability.

Required parts: ZKIT-731MEMO

The kit contains:

Part # Description QTY.

NJM78L06A 6 V AVR 1

1SS133 Diode 1

MTZ3.0JB 3.0 V Zener diode 1

CE04NW0J221M 220 µF, 6.3 V Electrolytic capacitor 1

C91-0457-05 0.022 µF ceramic capacitor 1

CK45B1H103K 0.01 µF ceramic capacitor 1

RD14BB2C103J 10 Kohm, 1/6 watt resistor 1

RD14BB2C102J 1 Kohm, 1/6 watt resistor 1

RD14BB2C472J 4.7 Kohm, 1/6 watt resistor 1

RD73FB2A472J 4.7 Kohm, 1/10 watt resistor 2

- Disconnect the power supply, antenna, and microphone.

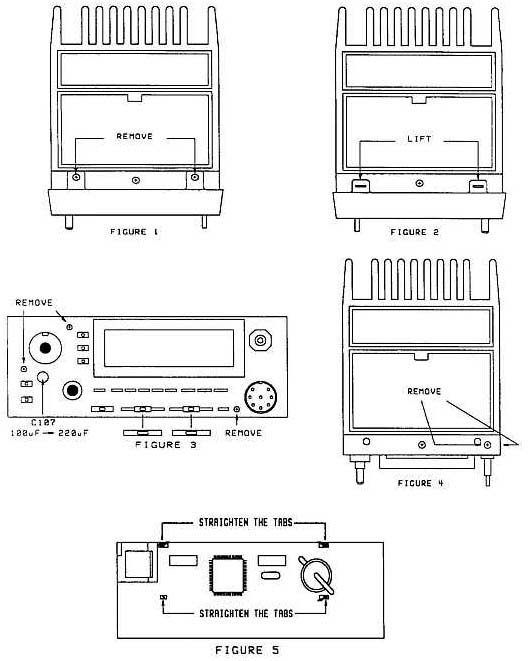

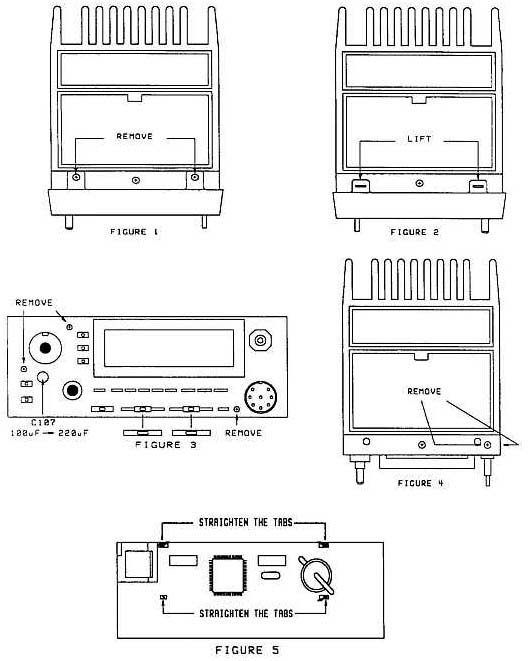

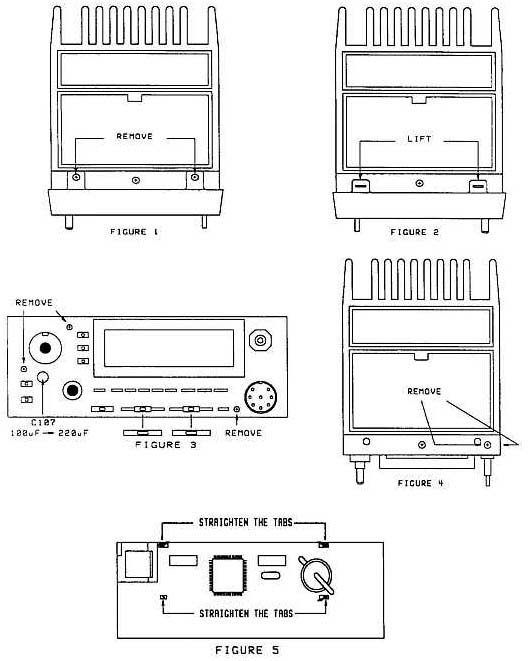

- Remove the top and bottom covers (12 screws). Do not damage the speaker

wires when removing the top cover.

- Pull the Main Encode, Volume, and Main Squelch knobs off the front panel.

If a knob does not easily pull off, wrap a cloth around the knob and carefully

pull it off with a pair of pliers. Be careful not to crush or scar the

knob.

- Remove the two brass colored screws from the top of the plastic front

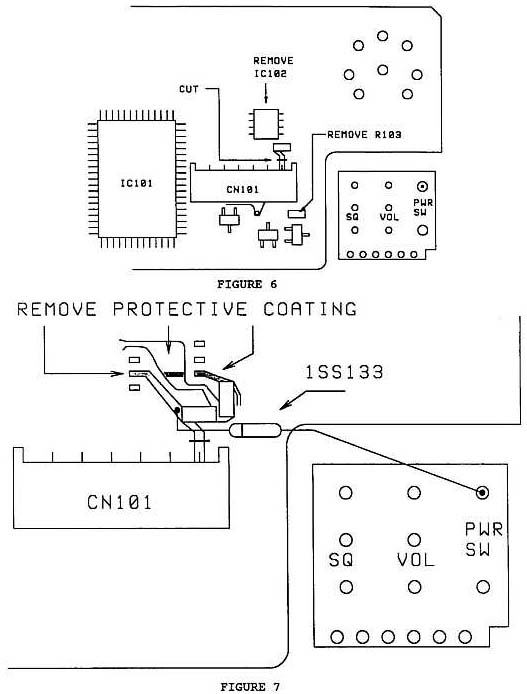

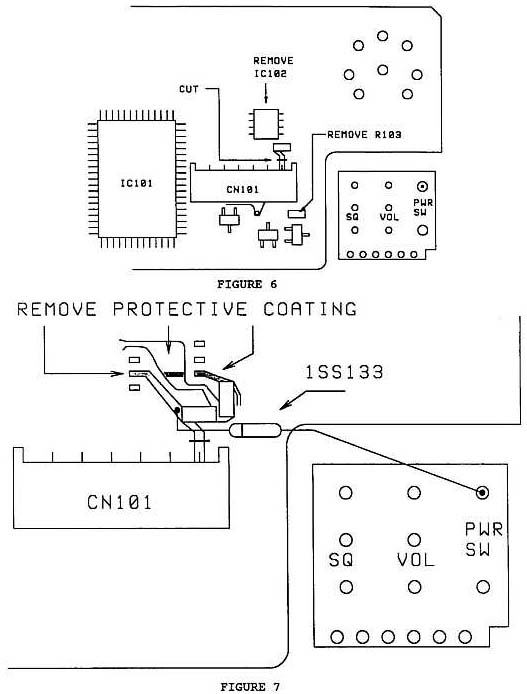

panel. Figure 1.

- Gently lift the two tabs on the bottom of the front panel and then pull

the front panel off the transceiver. Figure 2.

- Remove the two black shades from the Balance and Sub-Squelch controls.

Figure 3.

- Remove the three brass colored screws from Control board B/3. Figure

3.

- Remove the brass colored screw that is mounted on the front panel chassis

above the Power switch. Figure 4.

- Remove the brass colored screw that is mounted on the front panel chassis

to the right of the microphone jack. Figure 4.

- Carefully pull Control board (B/3) away from the body of the

transceiver.

- Disconnect the two "wire type" cables from the body of the

transceiver.

- Disconnect the two flex cables from the Control board. The flex cables

simply pull out of the connectors.

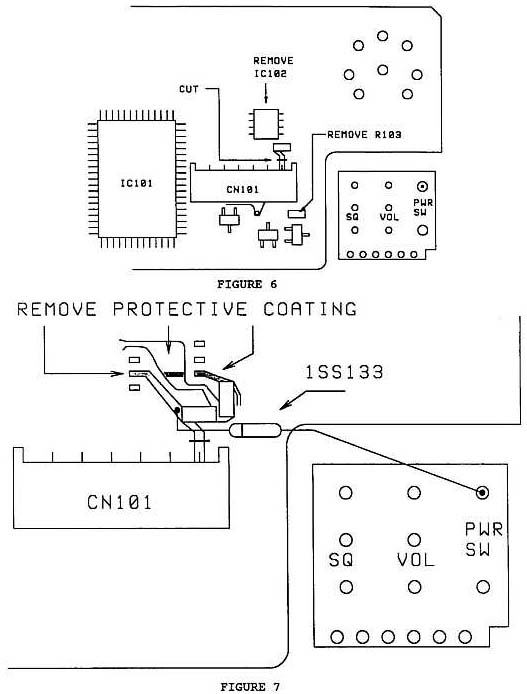

- Remove IC102 from the Control board. Since this device is glued to the

board, use a needle tip tool to lift each pin as you melt the solder. Then pry

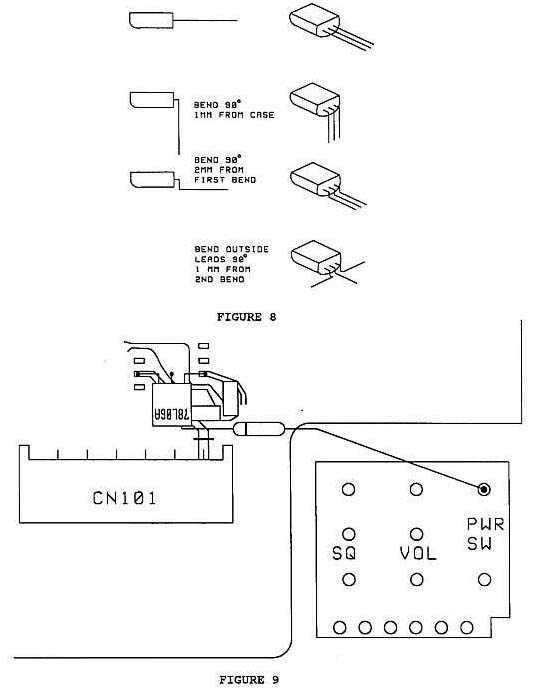

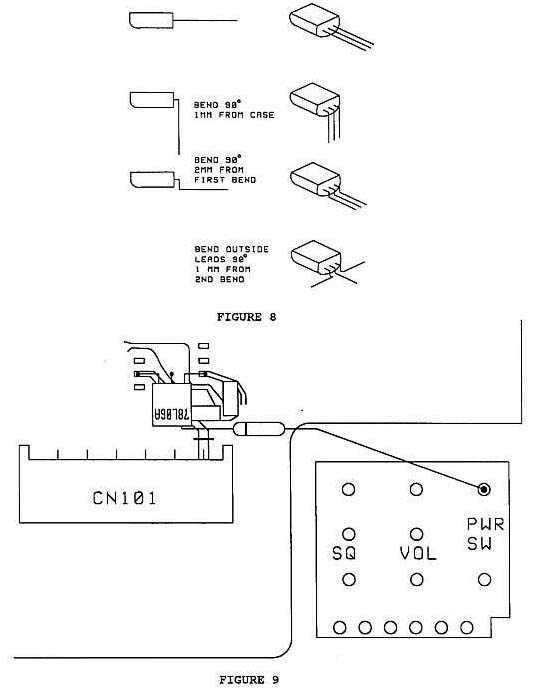

the chip off the board with a craft knife. Figure 6.

- Remove any excess glue and solder from the area where IC102 was

located.

- Remove chip resistor R103. Do not melt connector CN101. Figure 6.

- Cut the foil pattern between connector CN101 and chip capacitor C102. Make

the cut as close to connector CN101 as possible. Figure 6.

- Prepare the 1SS133 diode for installation. The cathode lead will be cut

and bent 90°. The diode must lay flat on the board and the cathode lead cannot

touch the cut in foil. Once the diode leads are prepared, solder the diode in

place. Figure 7.

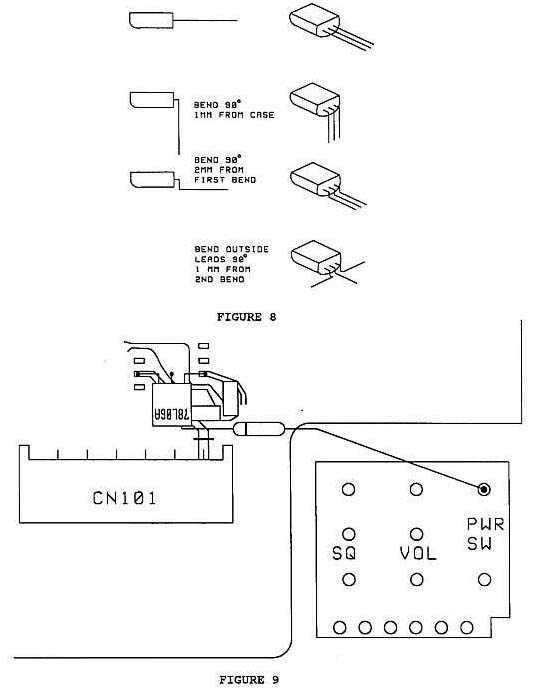

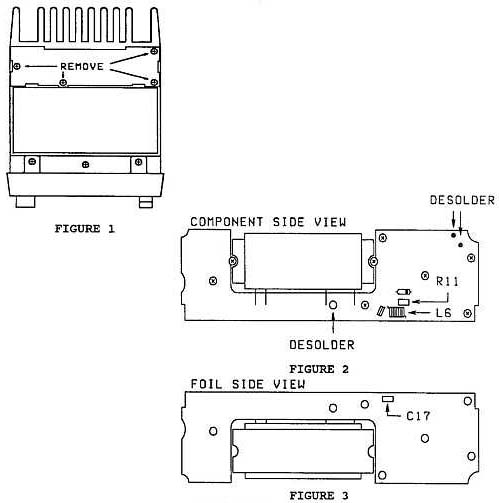

- Prepare the NJM78L06A 6 V AVR for installation as shown in figure 8. The

leads to this device are vary soft and can break when bent too often. Make

each bend only once.

- The 6 V AVR will be mounted in place where IC102 was located. The board

must first be prepared for the installation. Remove the protective coating

from the foils as shown in Figure 7. These are the foils that where connected

to pins 2 and 7 of IC102 and the ground foil that runs under the

device.

- Place the 6 V AVR on the board and make sure the leads contact the foils.

Cut the leads to size and then solder the device to the board. Figure

9.

- Prepare the 0.01 µF capacitor, 10 Kohm resistor, and 4.7 Kohm resistor for

installation. Place the parts on the board to size and cut the leads. Once the

parts are prepared, solder them to the board. Figure 10.

- Locate R105. If the component is 47 Kohm, change it to a 4.7 Kohm chip

resistor. The component's value can be determined by the numbers written on

the case. If the device is labeled 473, it is a 47 Kohm resistor and needs to

be replaced. If the device is labeled 472, it is a 4.7 Kohm resistor and does

not need to be replaced. Figure 10.

- Straighten the tabs that hold the LCD assembly to the…………. The rest of the

composing is missing, mail me if you have

it.

- This point is missing, please mail me if

you have this.

- This point is missing, please mail me if

you have this.

- This point is missing, please mail me if

you have this.

- This point is missing, please mail me if

you have this.

- This point is missing, please mail me if

you have this.

- This point is missing, please mail me if

you have this.

- This point is missing, please mail me if

you have this.

- This point is missing, please mail me if

you have this.

- This point is missing, please mail me if

you have this.

- This point is missing, please mail me if

you have this.

- This point is missing, please mail me if

you have this.

- This point is missing, please mail me if

you have this.

- This point is missing, please mail me if

you have this.

- This point is missing, please mail me if

you have this.

- Slide the lock, balance, and Sub-Squelch controls to the left.

- Slide the Lock, Balance, and Sub-Squelch knobs on the plastic front panel

to the left.

- Gently install the plastic front panel on the front panel assembly. Do not

force the installation.

- Install the two brass colored screws on the top of the plastic front

panel.

- Install the Main Encode, Volume, and Main Squelch knobs.

- Remove the two screws from the small board where the positive power lead

connects on the bottom of the transceiver.

- Solder the remaining 4.7 Kohm chip resistor to the foil side of the board.

Figure 13.

- Mount the board and install the covers on the transceiver.

This modification may be covered under warranty.

Time required to perform

this modification is 1 hour or less.

21-04-2000 TM-731A/631A Final board C17

change

Author: Kenwood

Communication, inc.

Service Bulletin no. 977 (8-8-1990)

Bypass capacitor C17 on the 144 MHz Final board has been changed in

production from a "flat package" chip capacitor to a "cylindrical package". The

change prevents the capacitor from fracturing. If C17 fractures, the output of

the power module can burn C17, R11, and L6. Additionally, Q1 on the TX/RX 144

MHz board may be damaged.

C17 should be changed as a part of routine maintenance when a TM-731A/631A is

received for service. The new style capacitor part number is CK41FY1E102M. For

field service, a 0.001 µF, 25 V disc ceramic capacitor can be used.

The production change started at serial number 108xxxx.

To replace C17:

- Disconnect the power supply and antenna.

- Remove the top cover. Do not damage the speaker wires.

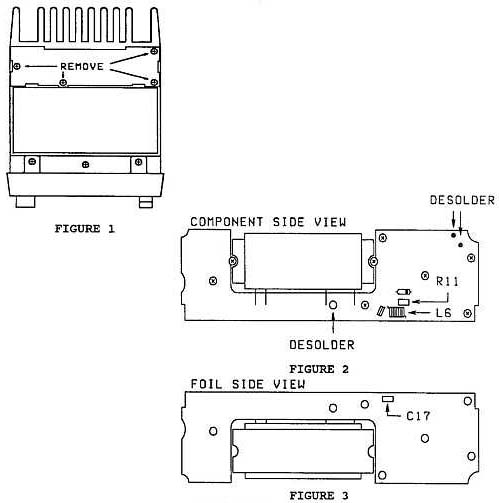

- Remove the shield plate from the VHF Final unit (4 screws). Figure

1.

- Remove the 7 screws that secure the final board to the chassis. Figure

2.

- Remove the 2 screws that secure the power module to the chassis. Figure

2.

- Remove the 2 screws that secure the VHF antenna coax to the heat

sink.

- Desolder the center conductor and shield of the VHF antenna coax from the

final board and pull the coax out of the heat sink. Figure 2.

- Desolder the terminal next to pin 3 of the power module. Figure 2.

- Rotate the board toward the front of the transceiver to expose the foil

side of the board.

- Inspect the solder at the terminals the antenna coax was soldered to. They

may need to be resoldered.

- Replace C17. Figure 3.

- If you are serving a TM-731A/631A that has been damage, check R11 and L6.

The coil may have pin hole burn marks in its insulation and the resistor may

be open. In addition, check Q1 on the RX/TX (144 MHz) board. If it is damage,

the receiver sensitivity will be low.

- If the Final board has been burned, it can be repaired. The carbon must be

completely removed from the board to prevent the board from burning any

further (carbon tracking of the RF signal). The burned area should be filled

with epoxy an the lands must be repaired.

This modification may be covered under warranty during the warranty

period.

Time required to perform this modification is 1 hour or

less.