In this information, when Holley is used, it refers Holley style carbs, such as Quickfuel, Pro-Systems, C&S, Demon, etc.

I've tried to organize the steps that follow in a rational manner. However, the steps may be dependent upon each other, so you will probably have to go back and forth some after an inital read.

1. Preparation.

Make sure the ignition is up to snuff. Check timing (base, mechanical, and vacuum). Check plug gap, condition, and heat range. Check wires and make sure no two sequentially firing wires are routed side by side. Air and fuel filters should be clean. When possible, do tuning with air cleaner in place. Verify fuel pressure and install regulator if necessary. Inspect/replace vacuum lines. If you're working with a used carb, when in doubt, rebuild it. Take your time and do it right the first time. Before disassembling, count the number of turns it takes to lightly seat the idle mixture screws. Also, make a sketch of the choke housing and linkage positions. Use these when you reassemble the carb. Disassemble and soak in carb cleaner. Rinse off thoroughly with Gumout. If the finish is not uniform, you can use a wire brush wheel and aluminum cleaner to give it that bare metal look. Check that all the surfaces are flat with a straight edge. Verify all the passages are clear by blowing through with air.

Use the proper rebuild kit. If you have an OEM application Holley, the parts books will not list the carb so you may need to contact Holley or Quickfuel for the proper rebuild kit part number. Closely compare the old parts with the new ones in the kit. Some of the kits have parts that don't quite seal or have slightly different threads and can cause problems. One thing to look out for is the power valve shoulder style. Some are beveled and some are flat If your original power valve shoulder is flat and you replace it with one with a beveled shoulder, it may leak. This can be difficult to diagnose because it will act just like a blown power valve but, when you inspect the valve, it will be fine. Some power valves have slightly different threads and can damage your float bowl threads when you tighten down the nut. Be careful when replacing the needle and seat assemblies. You can strip out the bowl threads if you over-tighten the locking screw. Also, don't use the needles that have the screw slot cut in the top, with a lock nut that locks down the threads. They are reknown for trashing bowls since the tendency is to over-tighten them. Use the original style that has the large headed screw that goes into the needle, and the hex adjuster piece below it used to turn the needle assembly up and down. If you can't find them locally, they can be had directly from Quickfuel.

If you do a lot of carb work, use coated gaskets that don't stick when you disassemble the carb. Coating with chap-stick also works in a pinch. Check that the little crimped on thing on the bottom of the accelerator pump (holds the check ball in place) is not loose. Re-crimp or peen if necessary. Check floats for "water logging" and pre-set the float drop. Make sure secondary diaphragm is not torn and is properly positioned. With carb fully assembled but still off car, fill carb with fuel and check accelerator pump for a strong squirt and check that the venturis pull fuel by blowing through them with compressed air. Different size check balls are used, so make sure you've got the right ones. Use black Permatex 300 (sparingly) on the little gaskets to hold in place and help sealing. Don't put high tension return springs on them, the main shaft bushings wear enough as it is.

Also, watch for backfires (install the check ball power valve protection kit if you carb isn't already so equipped). It's easy to get the timing off during a rebuild and get some backfires.

If you are running a blow through carb setup, with a turbo or Supercharger, you can not use a power valve protection kit, so it is best to use a power valve plug till the basic starting and idle are adjusted, to prevent blowing the power valve. Once it starts and idles good, put the power valve back in.

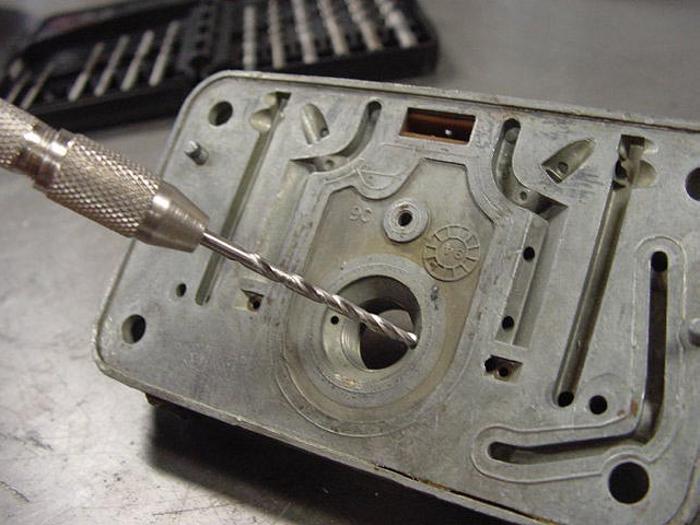

To build & install a power-valve protector, do the following: Disassemble the throttle plate from the carb body. There is a passage on one side of the throttle plate that connects the intake to the power valve. Find a junked bicycle wheel bearing or other source for approximately 1/8" ball bearing. Drill the passage not quite thru from carb side to intake side. Drop a Phillips screwdriver down the hole you just drilled and smack it once with a hammer, to make some crosses in the bottom of the hole. Then drop the ball bearing down the hole & reassemble. In operation, a backfire will lift the ball bearing up against the gasket between throttle plate & carb body, and seal off the connecting passage to the power valve before the pressure spike gets high enough to rupture the diaphragm. In normal operation, the crosses in the base of the drilled passage allow pressure to pass around the ball and the power valve functions normally. This operation takes about 2 hrs and requires disassembly.

Make sure venturi butterflys and the choke plate open fully. Check for manifold-to-head and manifold-to-carb vacuum leaks. If leaks are suspected, spray with the suspected leak location with Gumout or starting fluid (watch the paint). The engine should surge or stumble if there's a leak. Watch for fuel leaks. Some leakage from throttle shafts, when pumping the accelerator with the engine off, is normal. Soak it up before re-starting the engine. Shouldn't leak when running.

Be alert to carburetor flooding when fuel is first applied. Flooding can be caused by dirt, small particles of hose cuttings, flecks of RTV, etc. If flooding is apparent, tap the body of the carburetor lightly with the wooden handle of a small hammer. If flooding continues, pinch the fuel line hose to shut off flow, run the engine to clear the carburetor, and let the fuel line flow again. If flooding still continues, disassemble and clean.

Fuel Pumps and Pressure Avoid extremes in fuel pressure. At IDLE, there should not be any more than 6.0 - 7.0 psi; if the vehicle has an adjustable fuel-pressure regulator, set it to 6.5 psi. With most fuel pumps the minimum fuel pressure is encountered at high rpm and WOT. Fuel pressure should not drop below 3.0 psi. If it does, a fuel pump with more capacity may be required. Note that some later model vehicles (the 5.0L Ford is one example) have mechanical pumps that will give more than 6.0 psi at idle. The vehicle will perform well, but may be prone to stalls on quick turns and stops with the clutch disengaged. If this problem occurs, check the fuel pressure. If it is more than 7.0 psi at IDLE, it should be reduced through the use of a regulator. Always use a filter between the pump and carburetor. Note that a good filter is large in area, so it may be able to transmit a significant amount of heat to the fuel. It is a good practice to keep the filter away from heat and not allow it to come in contact with any part of the engine.

Air Cleaners: Your carburetor was originally calibrated with a low restriction open element air cleaner configuration. A 14 x3 unit is best for most. It will perform using a variety of other air cleaner designs and will perform as intended with nearly any reasonable air cleaner design. With a 14x3, the carburetor does not exhibit excessive sensitivity to the air cleaner, there are several guidelines you should follow when selecting an air cleaner: Running without an air cleaner is strongly discouraged for a streetdriven vehicle. Dirt and varnish will accumulate in critical bleeds and upset the fuel metering. Dirt and debris may easily get into the fuel bowl through the bowl vents or larger bleeds and cause a multitude of problems. Any calibration testing should be performed with the air cleaner in place. Depending upon the air cleaner used, the metering typically will be leaner with the air cleaner in place. A large 14"x3" open element air cleaner offers almost no resistance to air flow. Flow bench results show virtually no reduction in air flow. Also, this design should cause no change to the fuel metering. A 10"x2" open element design will result in some definite air flow restriction but little change to the fuel metering. Elements smaller than 10"x2" are more restrictive and have the most effect upon metering. The fuel metering at WOT will be shifted LEANER, especially at higher rpm ranges. If you have a dual-purpose vehicle that is sometimes used in competition without an air cleaner, it may be necessary to have two separate calibrations. If you are running a smaller air cleaner and have optimized the WOT with it in place, do not be surprised to find that the metering shifts RICHER when the air cleaner is removed. This may require you to calibrate the WOT with leaner Jets and Rods at the drag strip. DO NOT allow the vehicle air-stream to blow across the top of the carburetor(s) such as on an open-bodied car or full-bodied vehicle with a tunnel-ram manifold. The flow of air across the carburetor will result in an upset to the fuel metering that cannot be accommodated by recalibration since the change to the A/F Ratio will be different for every vehicle speed.

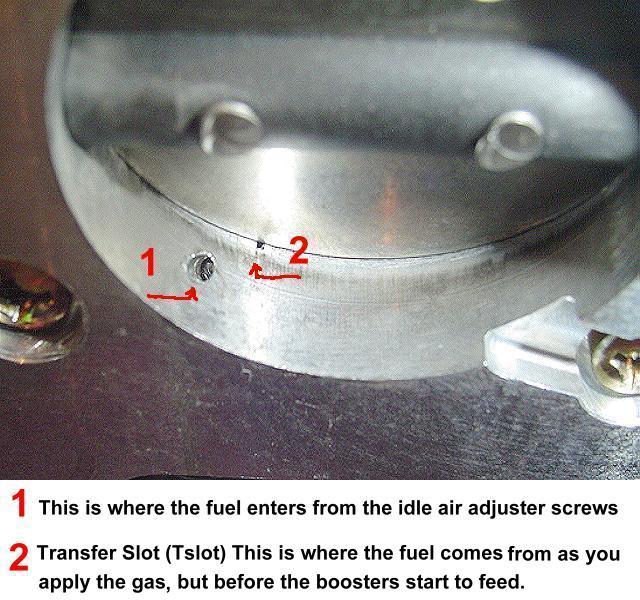

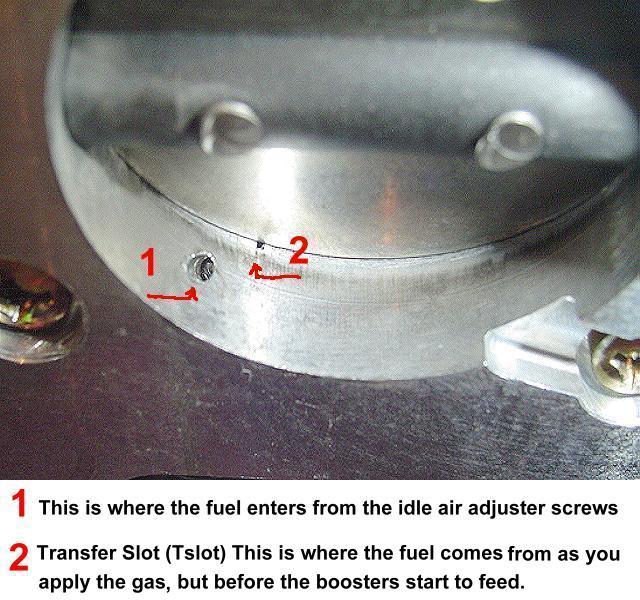

The Tslot should be exposed slightly as shown. Not having any showing will cause a stumble as you apply the gas from it going lean. Having too much exposed will feed enough fuel to the engine at idle, to make adjusting the idle air fuel screws not have any effect, making it idle too rich. It is best to set the Tslot so the opening that is exposed is as long as it is wide, square. After doing this, make your idle speed adjustment using the secondary idle adjustment screw. If you are running a real radical cam, this may not be enough to control the idle. If that is the case, drilling small holes in the throttle blades may be required to provide enough air to the engine, while the blades are nearly closed. On some older carbs you may have to remove the secondary adjuster screw from the bottom of the base plate and put it in from the top to allow easy access. The Tslot controls the fuel delivery until between 2200 and 2800 rpms in most engines when the fuel starts feeding from the boosters. If you are rich or lean before that, it is most likely from a idle air adjustment, Tslot, or emulsion circuit that feeds the Tslot causing the problem.

Note: Once I have my T slot set correctly, I put some red paint on it to remind me to use the rear idle adjuster to do any adjustments to idle speed.

If the carb is adjusted so the throttle blades are positioned as indicated, you should be able to adjust the idle air mixture so it idles well. If it is done this way, your jet size will have little effect on the idle, since the jets are not a factor until when the fuel is being pulled from the boosters, and they will not come into play while the T-slot is adjusted correctly. The Power Valve will not be in the circuit at this time either, so a high vacuum opening power valve can not cause a problem at low vacuum idle.

The rear adjuster on most carbs is done from the bottom. On some, you can take the adjusting screw out from the bottom, and put it in from the top to allow easy adjustment. If yours can not be done this way, Quickfuel sells a piece to allow that to be done easy.

Note: The idle circuit does have a slight effect through out idle, cruise, and wide open throttle, but your primary and secondary jets have very little effect on idle. If you are too rich at idle, changing the jets will have no effect. You could actually pull the jets out, and still drive the car. The idle and transition/transfer slot do all the fuel delivery from idle, to between 2,000 and 2,500 RPMs on most carbs, when the boosters start feeding. This is when the jets come into play. You can check to see at what rpm/vacuum your carb start feeding from the jets by having someone watch the tach, and slowly move the throttle while you watch the booster in the top of the carb. When you see gas coming from them, this is when you go from feeding from only the idle port below the throttle blades, and T-slot, to feeding also through the boosters.

Set the Idle Mixture.

A lot of guys change there main jets out to try to correct a idle problem. The main jets have little function until the boosters start feeding the engine, usually between 2,000 and 2,500 RPMs. You could actually remove the jets, and drive the car around your neighbor hood keeping the RPMs below 2,000.

Each primary (left and rigth) has its own mixture adjustement screw. On open plenum intakes, it's possible for an engine to have a fair idle with one side very rich and the other very lean. This is why you must adjust each side evenly, a little at a time. The same goes for dual planes, since most have a balance passage between the two sides. Also, there is some delay between changing the carb adjustment and the new mixture reaching the cylinders, so adjustments should be made slowly with an occasional pause to let things settle out.

If you don't have a starting point, turn both screws all the way in until they *lightly* seat. Then turn both out 1 1/2 to 2 turns, as required to make the engine run. Start engine, allow to warm, and set the initial idle speed (the idle stop screw, not the mixture screws) to keep the engine running. When starting the car after having the carb off or drained of fuel, have a helper spray Gumout carb cleaner to keep it running, otherwise it may lean out and backfire. Once engine is warmed up, check that choke is disengaged. If possible, perform the adjustments with the air cleaner in place.

You can get the mixture in the ballpark by picking the mid point between lean stumble and rich lope. Except for some emissions Holley's, turning the idle screws clockwise will lean the idle. Counterclockwise will richen the mixture. Screw one adjuster in until the engine starts to slow, then screw it out until the engine slows again. Set it to half way between the two points where the engine slowed, then repeat with the other adjuster. Iterate with smaller adjustments. Once a decent idle is found, readjust the idle speed.

Slowly turn in the first adjuster you adjusted, counting the number of turns. Sample, 1 1/4. Now set the other one, or if 4 corner adjusters, the other 3 to the same 1 1/4. Readjust the idle speed.

You can set the final idle mixture with a tach or with a vacuum gauge. Using a vacuum gauge, adjust the idle mixture screws obtain the highest vacuum reading. The gauge should be connected to a manifold vacuum carb port. Each screw should be turned an equal amount to keep the system balanced. Alternatively, you can adjust the mixture screws to get the maximum rpm. Start on one side, turning the mixture screw to obtain the highest rpm. If the speed changed by more than 50 RPM, then readjust the speed. Follow up with the other side, adjusting it to get maximum RPM. Reset the idle speed. Slowly trim each side to again get the maximum idle RPM. Go leaner just enough to get a 25 RPM drop in speed. Reset the idle speed to the desired RPM. This is a lean-best idle set. Setting richer than this will not improve idle quality or performance, but could tend to foul plugs.

Note:

Long duration cams with low vacuum may require modification of idle system. ...If the engine has a fairly radical camshaft it may require an excessive amount of throttle opening for idle and/or have low idle vacuum levels. Either condition can lead to poor levels of adjustability and erratic idles.

Another fix for the above condition is to run as much spark advance as possible at idle. If the distributor is fitted with a vacuum advance unit, connect it directly to manifold vacuum. If you are not able to employ vacuum advance for some reason, then the mechanical curve should have a low limit, which will allow you to use plenty of initial spark advance.

If the engine is very radical, and doing the above with the timing will not allow it to idle correctly, you may have to modify the throttle blades by drilling small holes in them. This will allow enough air to feed the engine. This is only needed on very radical engines, so is a last resort.

Install Proper Power Valve.

For a typical gasoline engine, maximum power is made with a fuel to air mixture that is considerably richer (25% or more fuel) than the cruise mixture. To provide additional fuel for high power or high load situations, Holley type carbs utilize a power valve circuit. When the vacuum level drops below a preset level, indicating a high power condition, the power valve opens and additional fuel flows from the power valve channel restrictions The PVCR's are the two small holes located behind the power valve.two little holes in the metering block which are hidden behind the power valve. The diameter of these holes determines the amount of additional fuel delivered, while the trip point of the power valve determines when it is delivered.

Holley makes several different types of power valve. There's a standard flow version, a high flow version (with larger openings), and a two stage version for heavy vehicles and economy applications. Holley rates it power valves by the vacuum level, in inches of mercury, at which they open. For instance, a number 65 power valve, opens at 6.5" Hg. Single stage power valves are available in 1" increments from 2.5" through 10.5". Note that some Holleys have power valves in both the primary and secondary sides of the carbs while others only have them on the primary side. Holley also makes a power valve plug that blocks all flow from the power valve circuit. This can be useful in certain tuning situations

A vacuum gauge is required to pick the proper power valve. Check the vacuum level at idle (warmed up and in gear if the vehicle is equipped with an automatic transmission) and at various *steady* cruise speeds. The power valve should be picked to open at 1 1/2" to 2" Hg below the minimum steady vacuum reading. For instance, if 11" Hg is the minimum observed, pick a #90 power valve (trips at 9.0" Hg). Don't use the generic un-numbered power valves that sometimes come with generic rebuild kits unless you test it first for the trip point.

Note that the power valve only determines when the additional fuel is added.

The amount of fuel added is determined by the diameter of the PVCR's. To

properly tune the power valve circuit to provide best power and best fuel

economy, the PVCR diameters may need to be altered. Unfortunately, this means

making permanent modifications to the metering block. If you want a very economical cruise, and still have the correct A/F ratio at WOT, increasing the size of the PVCR's, and dropping the size of the primary jets a few sizes is a good option. If you want to do this, I suggest either getting another metering block with adjustable pcvr's, or drilling your own, and threading them to take 6-32 air bleeds. I have these is mine, and it gives you complete adjustability. Quickfuel sells the metering blocks with air bleeds in the PVCR's.

Here is a good discussion on using air bleeds to adjust the PVCR, and other carb tweeks.

http://www.theturboforums.com/smf/index.php?topic=120084.0

If you have a Holley type carb that's not already so equipped, consider installing the power valve protection kit, unless you are using a blow through carb. It consists of a tiny ball that forms a check valve in a vacuum passage (?). During normal operation the check valve is open but when a backfire occurs, the valve quickly closes blocking the pressure wave from damaging the power valve diaphragm. The kit is inexpensive and comes with check balls to do two power valves, a drill bit, and instructions but no gaskets. Installation requires carb disassembly. A power valve protector can not be used with a Blow Through carb used with a supercharger or turbo.

Some drag racers prefer to plug the power valve circuit and rely on the metering jets only. To compensate, the main jets may need to be increased by 6 to 10 jet sizes. This is a drag race only modification. Don't try on a street driven vehicle. It will kill fuel economy and foul the sparkplugs.

Trial and Error the Main Metering Jets.

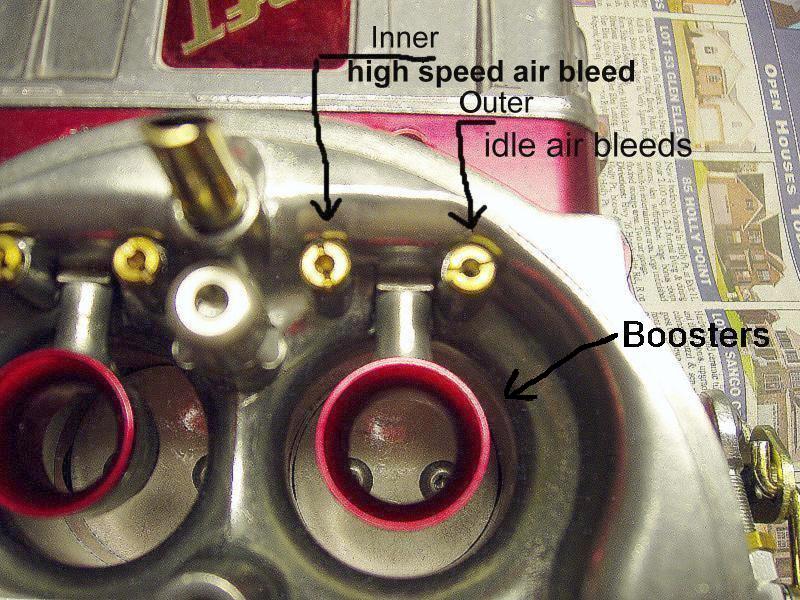

The main metering system is designed to supply the leanest fuel mixture for cruising in the 35 MPH and over range. Fuel from the main metering jet enters the main well and is mixed with air from the high speed air bleed. Engine vacuum pulls this air/fuel mixture and discharges it through the booster venturi and into the manifold through the throttle bores.

Carb jets are rated by their flow capacity, not diameter, and the jets are number-stamped on their side. The higher the number, the higher the flow and the richer the mixture. Entry and exit angles, diameter, and length all contribute to the flow rating. For this reason, simply drilling a jet to increase flow is discouraged. Quickfuel sells jets individually or as an assortment. Buy the assortment if you plan on doing some serious tuning.

The goal of main jetting is to go as lean as possible without misfiring or surging. This will provide the best cruise economy. Any additional fuel required for maximum power will be delivered, upon demand. by the power valve. Some sources recommend examining spark plugs to determine jetting but with the advent of unleaded fuels this has become much more difficult to do. A single jet size change is only a 4 1/2% flow difference, so jump two sizes at a time until you surge or misfire, then drop back by single sizes. Be aware that ignition timing changes can alter the the optimal jetting so you may have to iterate. If you must go up or down 8-10 jet sizes then you have a problem either with the fuel delivery system or the carburetor is wrong for your application. It's handy to have a means of changing jets without having to disassemble the carb. Quickfuel provides for this by offering fuel bowls (P/N xxxx) with external plugs that can be removed to provide access to the jets. Note that these quick change bowls are only compatible with center hung floats. There also aftermarket kits (Percys and Willys) that achieve the same end.

Dial in the Accelerator Pump

Any opening of the throttle causes the manifold pressure to increase, forcing the vaporized fuel in the air to liquify and come out of suspension. The droplets of fuel then get deposited on the nearest surface, usually the manifold walls. The effect is more pronounced when the throttle is opened more rapidly. Since much of the fuel is no longer in suspension, the mixture leans out. To counter this transient condition, an accelerator pump circuit is employed to mechanically pump a small quantity of fuel into the throat of the carburetor as the throttle is opened. The accelerator pump also bridges the gap between the idle and main metering circuits. .

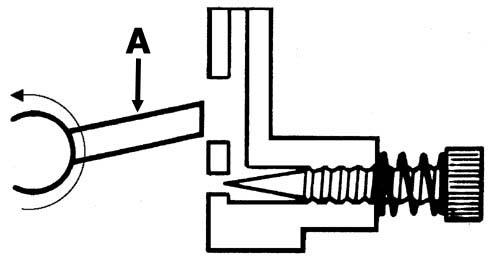

The Holley type accelerator pump system consists of three main components: the pump diaphragm, the pump cam, and the pump nozzle (a.k.a. squirter). The first adjustment to check is the clearance between the pump operating lever and the pump diaphragm cover's arm, at wide open throttle. This clearance should be around .015" to assure that the pump diaphragm is never over stretched at wide open throttle. Lack of clearance will eventually cause the pump to fail. When the linkage is properly adjusted, the accelerator pump arm should move the moment the throttle begins to move. Adjustments are made by turning the accelerator pump adjusting screw that is located on the accelerator pump arm, together with the pump override spring and lock nut.

The amount of fuel that can be delivered by one accelerator pump stroke is determined by the pump's capacity and the profile of the pump cam. The period of time that it will take for this pre-determined amount of fuel to be delivered is affected by the pump nozzle size. A larger pump nozzle will allow this fuel to be delivered much sooner than a smaller pump nozzle. If you need more pump shot sooner, then a larger pump nozzle size is required. During acceleration tests, if you notice that the car first hesitates and then picks up, the pump nozzle size should be increased. A backfire (lean condition) on acceleration may also require a step up in pump nozzle size. If off-idle acceleration is sluggish then the pump nozzle may be too big.

The accelerator pump nozzles are stamped with a number which indicates the drilled pump hole size. For example, a pump nozzle stamped "35" is drilled .035". Pump nozzle sizes are available from .025" to .052". Whenever a .040" or larger accelerator pump nozzle is installed, a "hollow" pump nozzle screw, P/N 26-12, should also be used. This screw will allow more fuel to flow to the pump nozzle, assuring that the pump nozzle itself will be the limiting restriction in the accelerator pump fuel supply system.

Accelerator pump cams come in various sizes and are color coded and number coded. The cams have different shaped ramps that the arm from the accelerator pump rides on. By changing the size and shape of the arc on the cam, the pump shot can be tailored to start early or later as you go from off idle to full throttle. There are also two holes in each cam. Changing the cams or holes can have an effect on the way a vehicle leaves the start line in a drag race. If you leave the line off idle or at a higher RPM (while foot braking or when using a trannie brake or when using a clutch with a manual transmission) experimenting with the pump cams may help. There is no set rule for use, you just have to experiment with the different cams and the different cam positioning holes in the throttle linkage of the carb. You can buy individual cams or an assortment (p/n xxxx).

Pump shooters are another area of experimentation. Holley type carbs come with a standard shooter size which differs by carb list #. If you are experiencing a bog or hesitation off idle, you can try a larger, higher # shooter size. The bog or hesitation may be caused by a momentary lean condition when the carb goes from the idle throttle position to the main metering system. The shooters help richen this momentary condition and eliminate the stumble. Keep going up in shooter size until a puff of black smoke comes out the exhaust, then go back one or two sizes. Playing with the shooter sizes is particularly helpful, when you have an intake with a large plenum area, such as a large open plenum or a tunnel ram.

Avoid the big 50cc pump if at all possible. For most applications, the standard 30cc pump is sufficient.

Adjust the Opening Point of Vacuum Secondaries

The opening rate of a vacuum secondary system is controlled by the diaphragm spring located in the vacuum secondary diaphragm housing. A lighter spring will allow the secondary throttle plates to open more quickly. Likewise, a stiffer spring will delay the secondary opening. Holley makes a spring assortment kit (P/N 20-13) for tuning purposes. The color-coded springs run from light tension to heavy:

White - Weakest

Yellow (Short Spring)

Yellow

Purple

Plain (Steel grey)

Brown

Black - Stiffest

Or you can get an adjustable one from Quickfuel.

If there is a bog or hesitation when the secondaries open, the spring tension is too light, go to the next heavier spring, or adjust the adjustable one. If you are a bracket racer and are using a carb with vacuum secondaries, you can adjust the throttle plates for changes in weather and track conditions or for changes to your "dial in".

If you're tuning at a drag strip, pick the secondary diaphragm spring that gives the quickest 60 foot time (without bog or hesitation). Sometimes, it requires a lot of fuel to cover up the lean pump shot on the primaries. The spring will also affect mileage, lighter the spring, the more performance and lower mileage you will get. When you have the mixture right, the secondary spring can be very light. If you're changing springs for the first time, install the stiffest and then try lightest spring to get a feel for the effect.

While you can adjust for some mechanical opening , don't be tempted to convert to mechanical secondaries by putting a screw in the linkage of a vacuum secondary carburetor to force the secondary throttle plates open. True mechanical secondary Holley type carbs have a second accelerator pump to inject additional fuel to cover the lag between the airflow and the fuel metering, just like on the primary side. Without this secondary accelerator pump, the engine may go to lean and backfire.

Note that you can't easily verify secondary operation when the engine is unloaded because the vacuum level won't drop. Sometimes you can fool the secondaries by revving the motor and stuffing a rag over primaries forcing the engine to pull from secondaries. Be careful though, you don't want to suck the rag down the motor.

Select Secondary Metering Jets

Pick the secondary metering jets that give the best time over a given distance (stay in a single gear to eliminate the influence of shifts) or best power on dyno. Keep increasing jet size by two sizes until you slow down then go down by one until the best jet size is found.

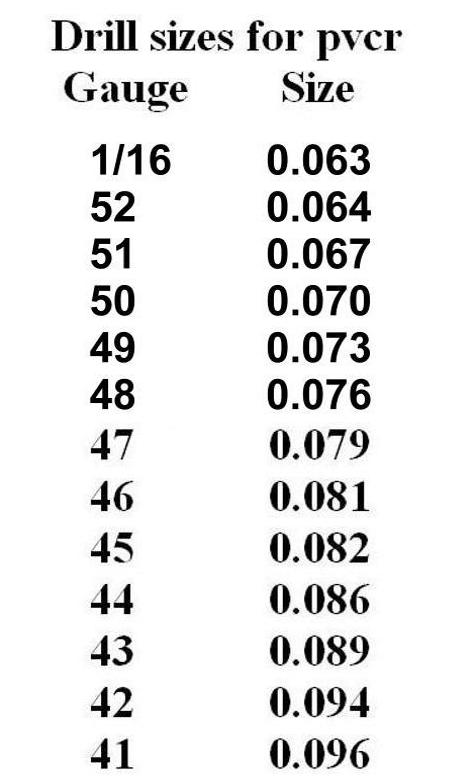

Optimize the PVCR's

As noted in step X, the PVCR's (the two little holes in the metering block which are hidden behind the power valve) determine the amount fuel added during high power or load situations. If you wish to set a carb up for best cruise economy and best wide open throttle power, you're probably going to have to alter the PVCR's. Unfortunately, Holleys do not provide a convenient means of adjustment. Changing the PVCR's means drilling the orifices larger or epoxying them shut and drilling a smaller hole. Note that it may be easiest to drill right next to the epoxied hole, rather than drilling the epoxy itself. Use a small number drill in a pin vise. Quickfuel sells carbs and metering blocks with replacable PVCRs.

For most applications the difference between lean best cruise and maximum rich power is on the order of 25%. This requires a PVCR approximately half the diameter of the main jets, after you are finished jetting. For whatever reason, Holley often makes the PVCR's much larger than necessary. I had a Holley 780 with primary and secondary side power valves and the orifices were approximately the same size as the jets. Don't be surprised if the PVCR's in your carb are this way.

Quickfuel, and a few other performance carb companies now have metering blocks that allow easy adjustmet by having the PVCR use replacable air bleeds as jets. You can remove them, and insert larger ones to richen up your WOT A/F ratio. the

10. Compensate for Altitude and Temperature Changes

Carbs are calibrated for sea level operation and an inlet air temperature of 70 degrees Fahrenheit. Once you know the correct stock jetting for your particular Holley carb, you can determine whether you live or race at an altitude above sea level. For every 2000 foot increase in altitude, you can reduce the jet size by one size. If you had a carb which has a stock jet size of 80 and you live or race at 2000 feet above sea level, then you would use a #79 Holley jet in the carb. Similarly, a change in the carb's inlet air temperature may require a change in the jet size from the stock calibration. Many racers go a step further by combining all of the weather variables, temperature, barometric pressure, dew point and humidity with the altitude of the track they are racing at to determine the "density altitude". This is a "corrected" altitude above sea level. From there they can determine whether a jet change is necessary to maintain performance or whether to change their "dial in" (if they are bracket drag racers).

The accelorator pump is their to cover the "bog" caused by the sudden gulp of air. On a Holley type carb you can adjust the pump

size, pump cam, and shooter size (some carbs have to be machined to adjust

shooter size). You can add 50cc pumps (Its been I while but I think thats the

large size) but you probably don't need them (they're for dominators and very

large secondaries - like spread bores). The accelorator pump cam should be set

to just open at what ever your nominal throttle possition is. For example - it

you launch at 3000 RPM, find out the throttle position to hold the engine at

that RPM and make sure the accelorator pump cam is just barely on the opening

ramp. You can also get different color cams - each has a different hight ( I

remember brown with 50cc pumps gave you something like a 38cc squirt of gas.

You can adjust the volume slightly with those screws on the accelorator pump

lever. The shooters control how much fuel flows and at what rate. The spring

/ screw combination controles the pressure (don't ever replace the spring with

a solid bar - something has to give - the levers will bend). Increasing the

shooter size too much will cause the car to react and then bog ( more

pronounced on oversize carbs ). Proper tune will allow the car to come of the

line without any extra fuel or any bog. Winter Fuel Idle Sets During the

winter months (in most parts of the country) the local fuel will be a "winter"

blend that is very volatile, as an assist to cold engine starting and

driveability during warm-up. However, the high volatility has the disadvantage

of allowing excessive vaporization of the fuel if the vehicle is operated in a

heated area such as a garage. This can result in problems in the idle-set

procedures since the carburetor's internal vents will allow this excess vapor

to be drawn into the throats and enrichen the mixture. The idle will be erratic

and not seem to be able to hold a set. To resolve this type of problem, it is

advisable to perform the final settings outdoors after the vehicle has been

stabilized with a drive of several miles.

several different power valves picture window is desired for high perf applications

don't forget to reinstall the check valve (pointed rod or ball) beneath the accelerator pump discharge nozzle (Don't Drop It) :)

if you running a cam with a bunch of overlap, it may be necessary to open the primary throttle plates quite a way to obtain the desired idle speed. When this happens, position may be such that no longer responds to idle mixture adjustments (transition slot uncover ). one way of compensating is to use the secondary idle speed adjusting screw to increase the opening of the secondary plates. this allows the primaries to close enough to cover the slot bring the idle circuit back into play. another way is to drill small hole in primary butterfly so that part of the idle air can flow through or four corner idle

idle and high speed air bleeds, good practice to give them a few shots of Gumout now and again to keep them clean

This section will attempt to remove some of the dark clouds of mystery surrounding carburetor jetting for those of you so inclined, with the warning that although not as complicated as you might think, it is still a long, time consuming job. I will talk primarily about the Holly carburetor, although the principles can be applied to the Ford.

First, a very brief primer on some of the functions of a carburetor. The carburetor serves two main functions:

1. To mix the proper amount of fuel with the proper amount of air.

2. To control the amount of air-fuel mixture introduced into the engine.

Let's look at the second function first. The throttle "butterflies" in the base of the carburetor. accomplish this control. We would use just one big throat and butterfly valve to do this, but the first function of mixing fuel with the air doesn't work very good unless the air is flowing very fast through the carburetor throat or venturi. So, we use four throats and don't even open the second two until the engine speed and load is enough to flow the proper amount of air. Contrary to popular belief, a 4-throat or 4-barrel carburetor is more efficient if properly jetted and sized, and will get better fuel economy than a two barrel (unless, of course, we are using the extra power available).

Now, the first function. Gasoline does not burn (it will extinguish a match thrust into the liquid, but take my word for it and don't try it because there is vapor all around). Only gasoline vapor in the proper mixture of air will burn. In an automobile engine, this can range from around 8 parts of air to 1 part of fuel (8:1) to about 17 or 18:1 (not counting the new "lean burn" designs). Best power for an engine like ours is about 12:1 and best economy is about 14:1 - 14:5 to1.

Believe it or not, you can actually run an engine by holding a sponge over the intake manifold and pouring a small amount of gasoline on the sponge. Not very efficient, so we want our carburetor to not only mix the air-fuel for us in the correct amounts, but also to know when we want power or economy.

Our modern Holley four-barrel carburetor with vacuum operated secondaries (the rear two throats) does this fairly simple.

1. Under cruise conditions, the fuel-air mixture is determined by the primary main jets (there are 2 of these for the front two primary throats).

2. Under full throttle, low engine speed, the fuel-air is determined by the primary main jets and the power valve channel restricters (PVCR's).

3. Under full throttle, high engine speed, the fuel-air mixture is determined by the primary main jets, the PVCR's, and the secondary main jets. The secondary main jets. The secondary main jets look just like the primary main jets, except they are located in rear float chamber for the rear two throats.

Notice the sequence of effects. This is the way we must determine our needs and on an engine that is used on the street, we are interested in economy as well as power. We can have our cake and eat it too!

The different circuits do a primary job, and then effect everything afterwards. In other words, the Secondary Jets effect high speed power. The PVCRs effect low speed power and high speed power. The primary jets effect cruise, low speed power, and high speed power. Therefore, unless you are setting up for all out race-only, the primary jets should be adjusted for best cruise and fuel economy.

PRIMARY JETS

1. Isolate the primary system by wiring the secondary throttle plates firmly closed. If you don't have vacuum operated secondaries, you must disconnect the secondaries and wire firmly shut.

2. If you have an Wide Band, operate the engine in the range of 2000 to 4000 RPM at a steady speed looking for approximately 14:1 air/fuel, changing primary jets to get this. This will get you a close approximation.

3. Now run the car on a straight and level road. Keep going to a smaller jet until you get a "Lean Surge". This is a feeling of the car surging back and forth while the accelerator is held steady. Richen back up (larger jet) until lean surge is just gone. Write this jet number down. This will be your primary jet eventually.

POWER VALVE

1. Now put in the next larger number primary jet, temporarily. The power valve on the Holley is replaceable, but only effects when the valve opens, not how much is flowed (assuming it doesn't restrict the flow). The actual flow is determined by the Power Valve Channel Restricters (PVCRs). Unfortunately, the PVCRs are not interchangeable jets, so they must be drilled out, or modified for using replacable air bleeds in them. This is why I told you to put one set richer primary jets in temporarily.

2. Make full throttle acceleration runs up to about 4000 RPM and drill out the PVCRs until you can determine no more improvement. Since you will go "too far" by perceiving no more improvement, you should be "right on" by going back to your "right" PRIMARY JETS. (BE CAREFUL! Over-drilled holes "can" be plugged up with lead in the event of a mistake and re-drilled, but it is a very poor fix.) This is why, for real performance use, it is better to drill, and thread them for the bleeds.

3. Put your correct PRIMARY JETS back in the carburetor.

SECONDARY JETS

1. Now, you can un-wire your secondaries, and change the secondary jets to get best acceleration overall, paying most attention to over 2000 RPM.

The above will give you your "cake and eat it". Most procedures have you change primary jets for power. This is wrong unless you are interested in race-only performance with no interest in economy. This is a long procedure but if used can give you the best performance , with fuel economy in the range of twenty or more miles per gallon (assuming you aren't using too big of a carburetor).

1. Holley jets all of their carbs to run just right at sea level (0', mean sea level.)

2. Use the butt end of a good set of number drills (very gently) to gauge the actual diameter of any jets or orifices which are not labeled. Keep notes for reference.

3. Main jet diameter varies proportionally to venturi diameter to get the same mixture ratio with all other factors constant.

4. Always go to the jet size tables, and use actual jet diameters for the calculations describe herein. Only convert your calculated jet diameters back to jet numbers using the tables just before selecting and installing actual jets.

5. At high altitudes (actually at any altitude above 0' msl.), the diameter of the main jets varies proportionally with the fourth root of the air density ratio at a particular altitude in order to maintain a constant mixture ratio at that altitude. For instance, if Holley used a .100" diameter main jet for a standard (sea level) setting, and your local density ratio is .8, you should use a .946" diameter main jet in order to maintain the correct mixture ratio.

6. The two little holes in the metering block which are hidden behind the power valve are part and parcel of the main jet setting. These are called Power Valve channel Restrictors. (PVCR)

7. If you want to set a carb up to cruise at a stochiometric fuel-air ratio (high vacuum, power valve closed, best fuel mileage), and have the ideal mixture for maximum power at wide open throttle (power valve open), these little "power valve metering orifices" should be exactly one half the diameter of your main jet orifices when you are all done jetting. This ratio of orifice size to jet size will give you a 25% increase in fuel flow This 25% increase is exactly the difference in fuel flow required to make the difference between a stochiometric and a best power fuel air mixture.

8. Older Holley's generally made the PVCR's on its general application carbs WAY bigger than what would be indicated by this 25% rule. I've even seen some that are as big, or bigger, in diameter than the holes in the main jets! No wonder the gas gauge jumps when you mash the throttle! And no wonder your rings, piston skirts, and bores wear out so quickly!

9. On the other hand, if you check out the stock jetting on a carb like a 4150G on a heavy truck, you will find that Holley applies the 25% rule almost without exception in these very demanding applications!

10. The best way to get the oversized PVCR's back to what you need on a carb like a 1850, a 3310, or a double pumper is like menthoned earlier, and install replacable air bleeds in these passages.

11. A 4150 with no power valve in the secondary metering block will want what appear to be oversized main jets compared to the primaries at wide open throttle (full power) because there are no PVCRs to flow part of the fuel. In fact, the math works out that the diameter of a secondary jet with no power valve should be 1.118 times the diameter of a primary jet with a properly sized PVCR, provided that the venturi sizes are the same.

12. The primary factor other than venturi size which will affect the relative size of the main jets from the primaries to the secondaries is the main air correction orifice. These are the little brass orifices which can be seen looking down the top of the air horn. There are two orifices in this location for each barrel. The other one is the idle air corrector orifice. At any rate, and in general terms, a .006" smaller diameter main air corrector orifice will require a .002" smaller diameter main jet diameter in order to get the same fuel-air ratio with all other things remaining constant. Use this rule to determine whether your carb is giving the same mixture ratio from the primaries as from the secondaries.

13. You can get quite accurate results by multiplying the various adjustment ratios described above together.

14. Always use a power valve with a setting number (the number is the amount of vacuum in inches which is required to hold the valve closed, for example: 5.0=5.0 inches of vacuum) which is at least 2 less than the amount of vacuum which your engine will maintain at idle. Always take this vacuum reading AT YOUR OPERATING ALTITUDE!

15. On an engine with a well designed, two-plane, equal length runner, intake manifold, with symmetrically located intake ports, it is rarely necessary to bias the jet settings from front to back or from side. Occasionally, if you are really picky, the side of the carb over the side of the manifold which has longer runners from the carb down to the plenum will want one size bigger jets, both in the primary and secondary barrels.

16. A good way to avoid too much nonsense with the size of the PVCR's during the jetting process is to install a power valve plug in the primary metering block (and suitably bigger main jets) while doing your timed runs, runs up your favorite grade, dyno runs, full throttle plug cuts, or whatever else you do. After arriving at ideal maximum power main jet sizes with the (primary side) power valve blocked, just install primary main jets which are 0.894 times the diameter of the main jets which were right with the power valve blocked out, make the PVCR's 1/2 of that diameter, and install the right power valve.

Air Density Ratio Chart

If you are going the dyno tune route, disable the secondaries, put a plug in the power valve, and figure out the leanest primary main jet size that will make it butter smooth on the street before going to the dyno. Stay with this main jet size when you are all done, just adjust the primary PVCR size based on what the dyno indicates is the best for power. This will make it drive like an absolute sweetheart, plus get great gas mileage. Another thing which will help street manners AND fuel mileage a BUNCH is putting one of the Crane adjustable vacuum advance pots on the distributor and fiddling with things until just right! Pipe FULL manifold vacuum (not ported vacuum) to its pot, and use one of the Crane adjustable pots on it. Adding vacuum advance to a mid sixties hi-po or fuelie Vette used to be worth 2.5 to 3.5 mpg on the highway, plus much more polite street manners, and much cooler running around town. Well worth it! Having the vacuum advance will probably let you go a jet or two, maybe even three, leaner on the primaries and still get good behavior.

If your engine is a wee bit cammy. One of these days, I'll have to explain how one goes about drilling little holes in the primary AND secondary throttle plates, on the side of the plates opposite the idle mixture feed holes and slots, so as to get the tip in of the transition slots to happen EXACTLY right when coming off of idle. There is a whole 'nother WORLD of insanely quick, sharp throttle response in this little fangle!! Among other things, it lets you avoid the need for SOGGY rich pump cams and squirters! Would not be surprised if the stumble you have when opening the secondaries is coming from the throttle stop for the secondaries being mal-adjusted!

Power valve might be opening a tad too soon but vacuum just doesn't seem to vary that much between idle and WOT.

???? Try the lightest secondary actuator diaphragm spring you can find --you might be in for a BIG surprise!! Ypu may not be drawing enough air to open things up wide before you are at a bazillion rpm. Also--might check SECONDARY idle air bleeds for blockages--mosquitos or such. Primary idle and main air bleedstoo.

Mains should be just big enough for it to drive smoothly (but not good power) with a PLUG in the power valve hole and secondaries disabled. Then get the PCVR to 50% of main jet diam. Then play with main jet, 1 leaner, two richer, to see if it is just right for power with the primary power valve in. If you end up going richer to get best power on the primaries, go back to the main jets that just made it driveable and smooth with the plug in the power valve, and enlarge the PCVR's one number drill size at a time until the full power mixture is right. If you have mechanical secondaries with a power valve on both primary and secondary sides, you need to run a plug in the secondary power valve hole if the car is quick enough for acceleration to uncover the power valve (by fuel slosh) and starve the secondaries. So, once the primaries are right, re-enable the secondaries, and play with the secondary main jets until you have the mix right for best power . Leave the primaries alone during this part--they are already right.

Holley had a funny habit of putting sewer size holes in for PCVR's on hipo carbs. I think they figured they were saving hot-rodders from burning pistons at full power when the got the mains too lean!! (But assumed that most hot rodders had no clue what the PCVR's were for!!) I have seen some PCVR's that were actually bigger than the main jets--an absolute joke for what they are supposed to do!! Also, after '67 or '68 crude emissions controls were a reality. So they tried to lean things out at part throttle, and then use enormous pcvr's to get some of the fuel back under load. Basically if you set the mains so the carb gives a decently smooth and driveable mixture at light loads, it will be STEEENKING rich at full power. Also some carbs from that vintage came those godawful two stage power valves--another abortion from that vintage of emission controls! Every 4150 I have ever looked at from a gas motor from a heavier truck--things like Mopar 413's, Ford 390's, 370/429's, and 534's, and IH 304/345/392's, 404/446's,401/461/478/549's, and 537/605's---ALL had pvcr's about 50% of the diameter of the main jets in their Holley's !!! I think that this is telling us something!! (Along with the fact that in going from best cruise mixture to best power mixture, you want about a 25% increase in fuel flow!) (50% of diameter = 25% of area.)

High flow power valve good, 2 stage bad. 10.5 probably wants to be an 8.5, if you are at sea level but that's later.

Carburator - Tuneup

1) First thing, adjust the fuel pressure! On carburetors, proceed to set the float levels too. Everything is relative to the float level / fuel pressure. If you change that, you start over.

2) Adjust idle to get maximum vacuum in gear (autos)(Note1) or in neutral (man). You will have to play with idle speed and richness settings, because they are interdependent, and when you change one, you change the other. Divide that number by two, and use that number for power valve selection (or enrichment activation). If the idle screws have no effect, or a perfect tune causes more than a 300 RPM drop in RPM when shifted into gear (note 2,4), remove the carburetor and turn over. Where are the throttle plates? There should be an idle discharge hole, and a transfer slot. If there is more than .020 showing of the transfer slot (Note 3), you need to drill a hole in each throttle bore on the transfer slot side, near the center. Start really small (1/32) and work your way up in size until the idle screws work again and you can idle properly.

This is how the front throttle blades should look from the bottom. If the tranfer slot is not showing, or has a lot more of it showing, it will cause problem.

3) Adjust accelerator pump so you have the shortest duration and volume that won't cause a bog under normal acceleration (no secondaries and normal throttle action). You should not be able to tell when the pump shot ends and the mains come on line. If the car bogs then goes, you need to increase the squirter size. If it goes, bogs, then goes again, you need to either decrease squirter size or increase pump capacity, possibly both. On FI, move the dial or map, on a carb, change the squirter or pump cam.

4) Adjust the secondary jets to give maximum acceleration or highest MPH in the 1/4 mile. Sometimes the secondaries will be leaner than the mains, if a secondary PV is used. On carbs without secondaries, try a high flow PV if lean. 4160 Holleys, and other carbs with non-adjustable secondary jets, as you will have to tune using a high flow / low flow / two stage power valve and main jets.

5) Adjust the secondary accelerator pump / diaphragm spring / air door to give the quickest 60 foot time (also without bog or hesitation). Sometimes, it requires a lot of fuel to cover up the lean pump shot on the primaries. On Holley vacuum secondary carbs, the spring will also affect mileage, lighter the spring, the more performance and lower mileage you will get.

6) Note vacuum on top end at full throttle. If carb is way too small, the vacuum will climb above the number you got in step number three. If this happens, take the highest reading you have, and add one. Replace (or add) the secondary power valve with this number, and go to step 5.

7) Adjust choke so under startup, no black smoke pours out, but no bog occurs either. All out drag tuning requires all jets to be equal on squarebore carbs, jetted for best MPH, and the accelerator pumps tuned for fastest 60-foot times. Chokes and air horns are normally removed. Sometimes the PV is (mistakenly) removed. If the PV is removed, the car will load up in the pits, because jet sizes need to come up about 10, causing an overrich condition at part throttle.

General thoughts on the matter: Increasing cam duration requires more jet. A dual plane manifold can use a much bigger carb. If you decrease the metering signal, you need to increase the jet (as you do when converting from a dual plane to a single plane manifold).

A blown power valve will have the greatest effect at idle and low RPM. You can check the carb by unbolting it from the manifold, putting the nuts back on the studs, and plopping the carb onto the studs. If you have an electric pump, turn it on. For a mechanical pump, completely remove the coil wire, and crank for about 15-30 seconds. The manifold and carb will be separated by a 1/2 inch or so, enough to see if any gas drips into the plenum when the engine is off (Don't try to start it!). If gas is present, check where it is coming from. There is a hole near the throttle plate that leads to the PV chamber. A blown PV will cause gas to drip from this hole(s). If it is dripping from the bores, the float level may be too high, or your carb has a crack.

The biggest city mileage killer is the accelerator pump. A bigger jet requires less accelerator pump, a smaller more. A dogleg style booster requires the most pump shot; the annular style the least.

The higher the velocity through the barrel, the better the atomization is. Better atomization means more efficiency (more MPG and Power). That's why dual planes typically give better MPG and performance up to the point where they start to choke off the upper CFM (and HP).

If you have a 600 CFM 4BBl carb on a true dual plane, the most any one cylinder can draw through the carb is 300CFM, where a single plane allows it to draw 600 (At its rated in. Hg, that is).

Note 1: This usually causes the idle circuit on auto transmissions to be slightly richer than need be when unloaded, but causes it to be perfect when you are actually driving it. Note 2: A lean idle circuit causes automatics to drop an excessive amount of RPM when put into gear and stopped, and may cause stalling. A richer idle is what is called for, unless you see black smoke pouring out the tailpipe.

Note 3: The transfer slot must show, or you will get a really bad off idle hesitation. For the best results, the transfer slot will look very close to a square hole. If not, set it that way, then adjust the idle speed with the rear adjuster. On engines with very radical cams, you may have to drill a small hole in each of the front throttle blades to give the engine enough air with the blades closed this far. If these don't work, you really shouldn't be running a 1050 Dominator on your 2-liter motor anyway.

Note 4: Sometimes, a really tight converter and a really big cam will do the

same thing, there may not be much you can do.

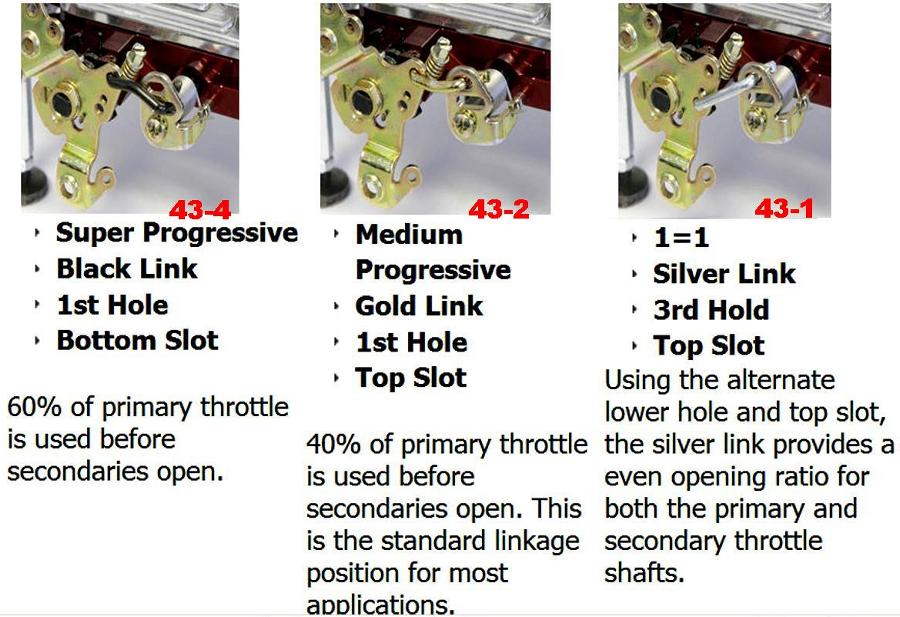

Changing the rate of opening of the secondaries

Another area that allows you to fine tune your carb to your type use, is different rate opening secondaries. Quickfuel sells 3 different links that change the way the secondaries operate. Most standard 4 barrel carbs start to open the secondaries at about 40% throttle. You can delay it up to 60 %, with a more aggressive link, or use a 1-1 link that opens the front and rear together.

| My Gun Pages | My Time in The Army | My Guestbook |