DIY Top Hat for Vertical Antenna

Have been reading about capacitance hats (top hats) for use with vertical antennas (VA3KOT article) and thought I'd put one together to test with once the weather warms up outside here in EN52 Chicagoland. Also ran across an internet video where the author used faraday cloth tape to apply to tie wraps as a construction approach. They had a follow on video exploring the tradeoffs of connecting (or not connecting) the top hat electrically to the top of the antenna.

I have some surplus rolls of adhesive-backed copper tape and picked up some plastic 24" tie wraps recently with thoughts of making a DIY capacitance hat for the top of my Chameleon SS-17 vertical antenna whip. As with many projects, I purchased the tie wraps and brought the copper tape inside to warm up, but set aside and have been busy with other things...

The last day in January 2026 brought more frigid temperatures to the area, and family tasks/projects lightened up enough to gather materials and tools and start this project.

The plan was to have four top hat elements and use a 3/8" grommet for interface to the whip (hopefully giving good electrical and mechanical contact to the top section). The adhesive-backed copper tape was wide enough to attach to and cover both sides of the tie wrap with one fold over at the top of the tie wrap (middle of the tape).

Formation of the tie wraps into a top hat ended up being pretty straightforward (see photos below).

A quick fit check on the top of the whip showed the 3/8" grommet was too large to fit snugly over the top element. It does fit well further down on the telescoping whip, but I wanted the capacitance hat to be at the top, not 2/3 of the way to the top. Time for Plan B.

I decided to not use the grommet and instead just tighten up the tie wraps at the center as much as possible to see how that worked out. Making them smaller worked pretty well to fill up the gap around the antenna element. A small plastic spacer was added to fill the gap.

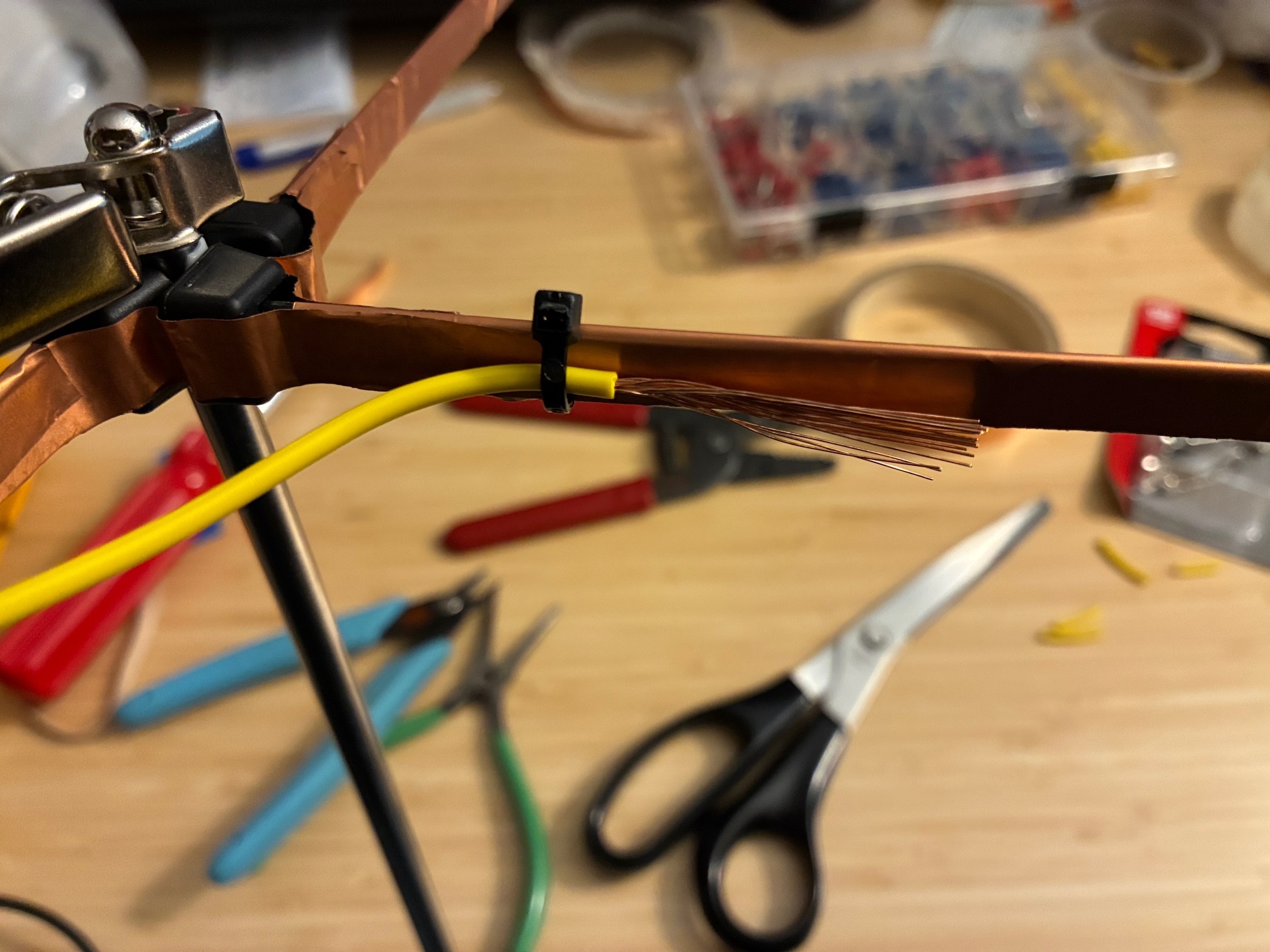

With that shape established, the copper tape was applied - first sticking to one side aligned with the bottom edge, then carefully folding over the tape to the other side and pressing down the length of the tie wrap. CAUTION: the copper tape has sharp edges and will easily cut your hands/fingers. Gloves are recommended for this step. See Lessons Learned below.

With the copper tape applied, it was starting to look more like a capacitance hat.

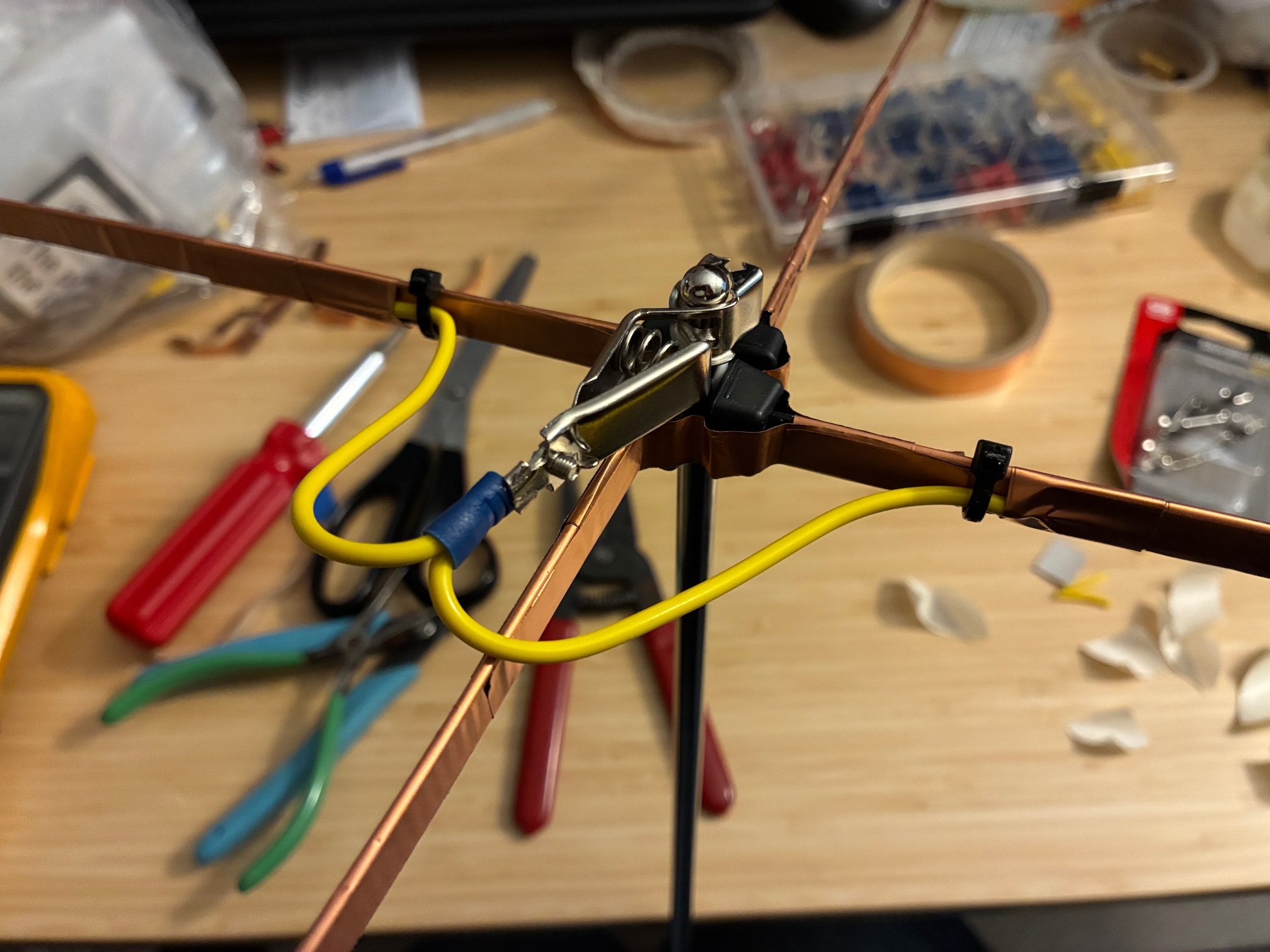

Without the tight fit of a grommet, I needed a way to perform two functions: make good electrical contact to the whip AND ensure that the top hat didn't slide down the antenna out in the windy big blue sky hamshack. A spring-clamp might perform these two functions, but was it workable and robust enough to survive outdoor use? Let's give it a try.

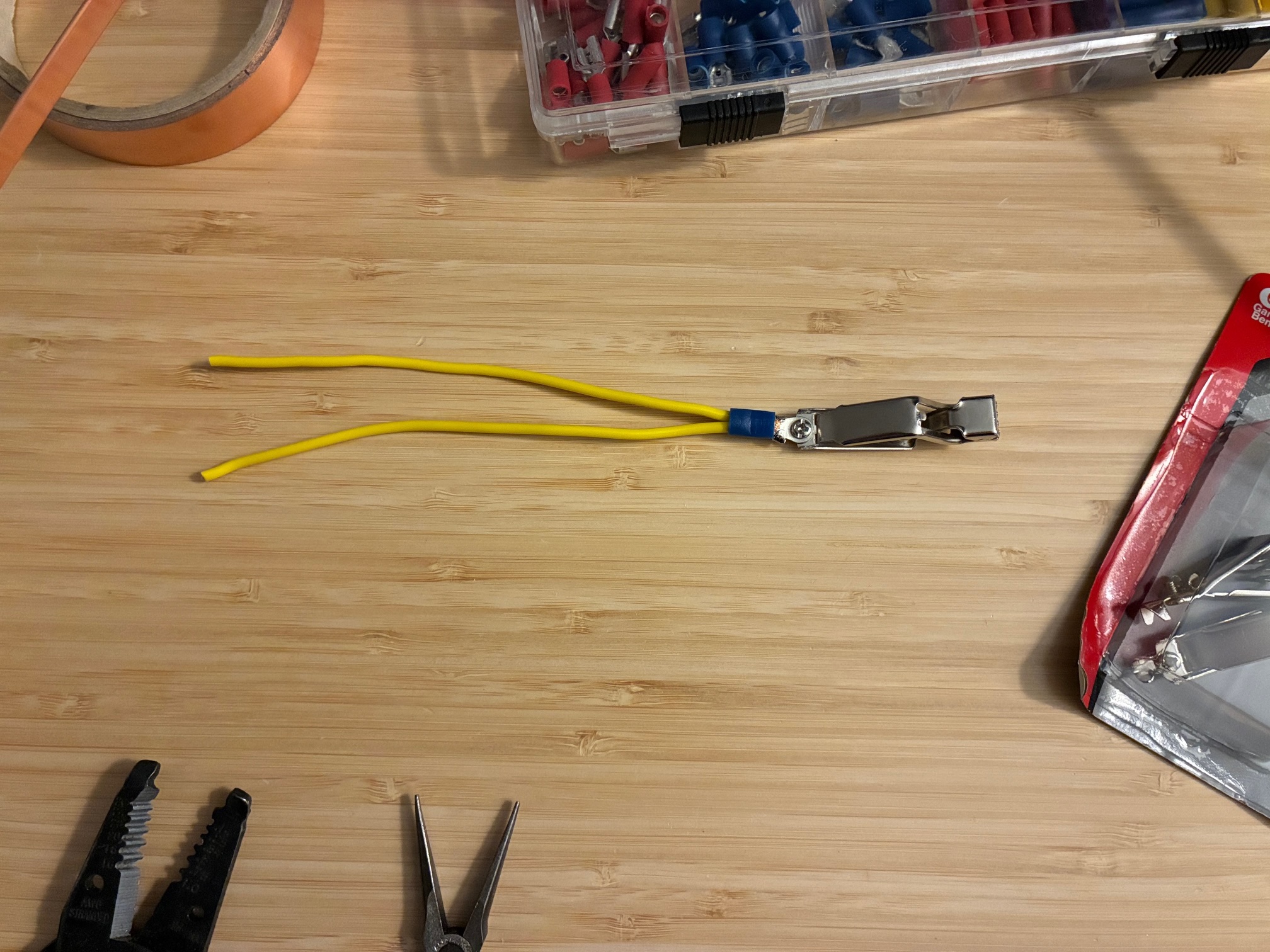

I had purchased some GB Charging Clips from the local big box store to build and attach Lazy Sloper wire elements to the top of the whip and had left over clips from that project (junk box to the rescue). A short length of wire originally purchased for radials was also available.

I wanted to hook to the top hat in two places (one is none, two is one) so cut the wire in two and crimped a lug onto it for attachment to the clip. If it had been above freezing in the garage, I would have cut some shrink tube and applied it over the terminal to the screw for the battery clamp, but BRR it is too cold out there for that. It is pretty secure already without that extra step.

The two ends of the wire were stripped back and secured along opposite side top hat elements.

More copper tape was applied to cover the connections. Again, too cold for soldering (can add later if needed when warmer outside). But, it is looking pretty good at this point. The large spring clamp provides the electrical connection to the top of the whip AND provides a mechanical support to keep the top hat from spinning or sliding down the top element. Win-Win!

With that, the assembly and ohm-out test is complete. The top hat is ready for outside testing!

Lessons Learned

- The 24" tie wraps yield a diameter of almost 4'. This was very ungainly to work with in my small office and 1/2 square meter desktop working area. Having an extra person stop by to hold all the flopping ends while adding the copper tape was a plus!

- The copper tape has very sharp edges with application down the tie wraps being a serious risk for a cut. Perhaps using the faraday cloth tape (as used by the internet video author) would have been a better choice for the conducting material added to the tie wraps?

- The assembled top hat is somewhat firm in holding the shape - leading to storage and possibly transportation challenges. Again, maybe the more flexible faraday cloth tape might have worked out better?

Project Results

With a little effort and a basic plan, it is possible to DIY build a capacitance hat for the top of your vertical whip antenna. With a well equipped junk box, this might be achievable at very low cost ($3.50 for the large tie wraps in my case).

Achievement Unlocked: Built a capacitance hat for the top of my CHA SS-17 whip antenna! Looking forward to testing this out in the spring!

All author photos taken with an iPhone 16e.